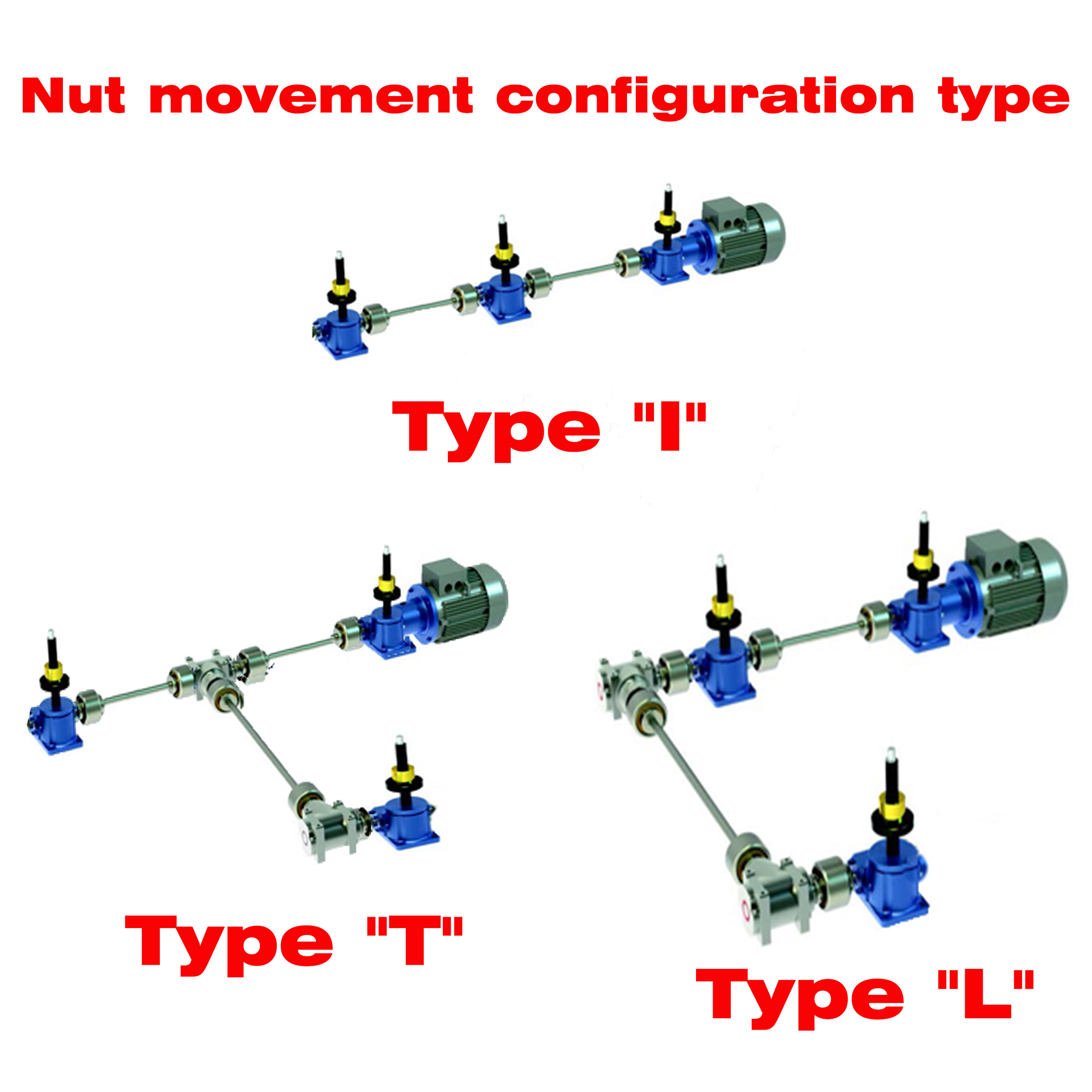

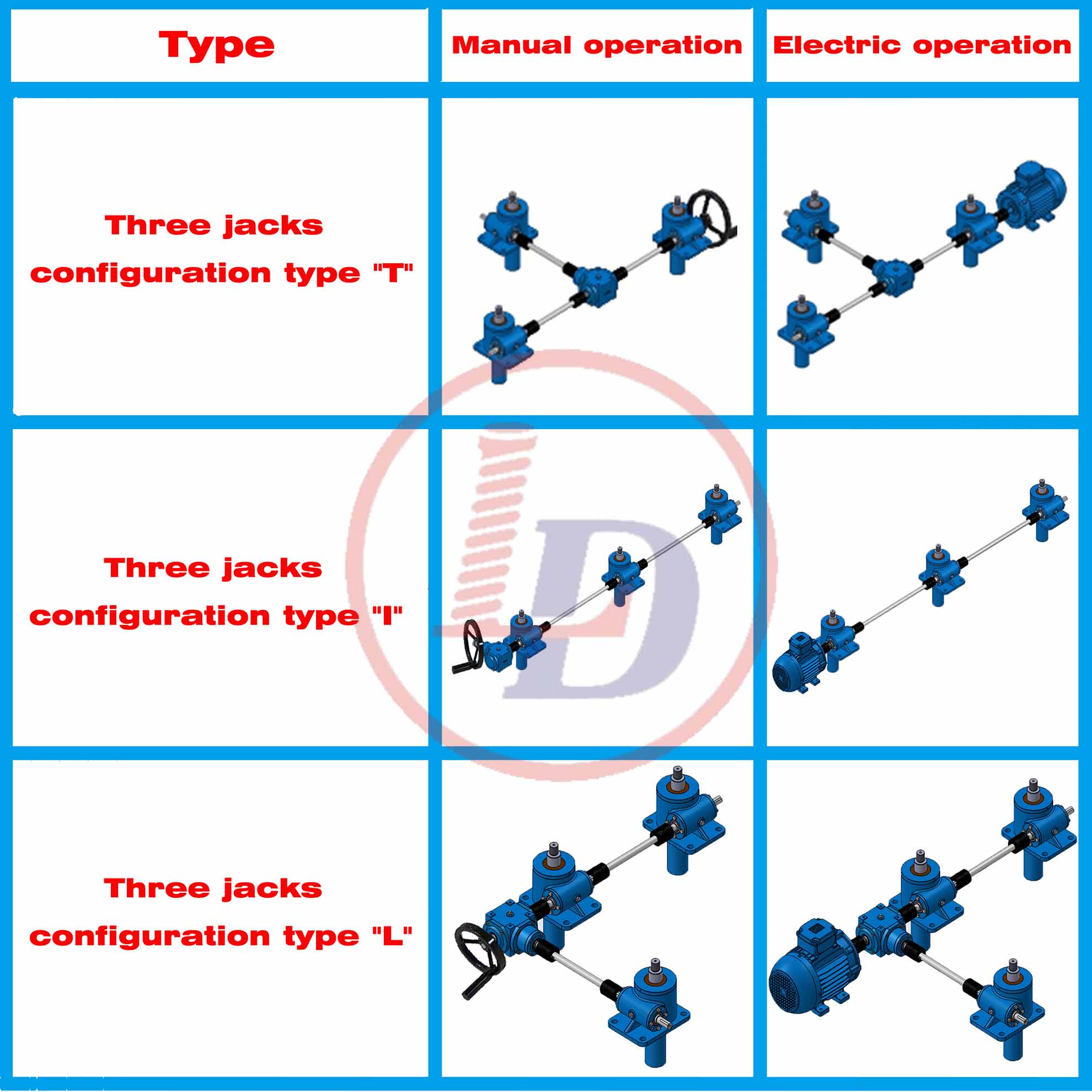

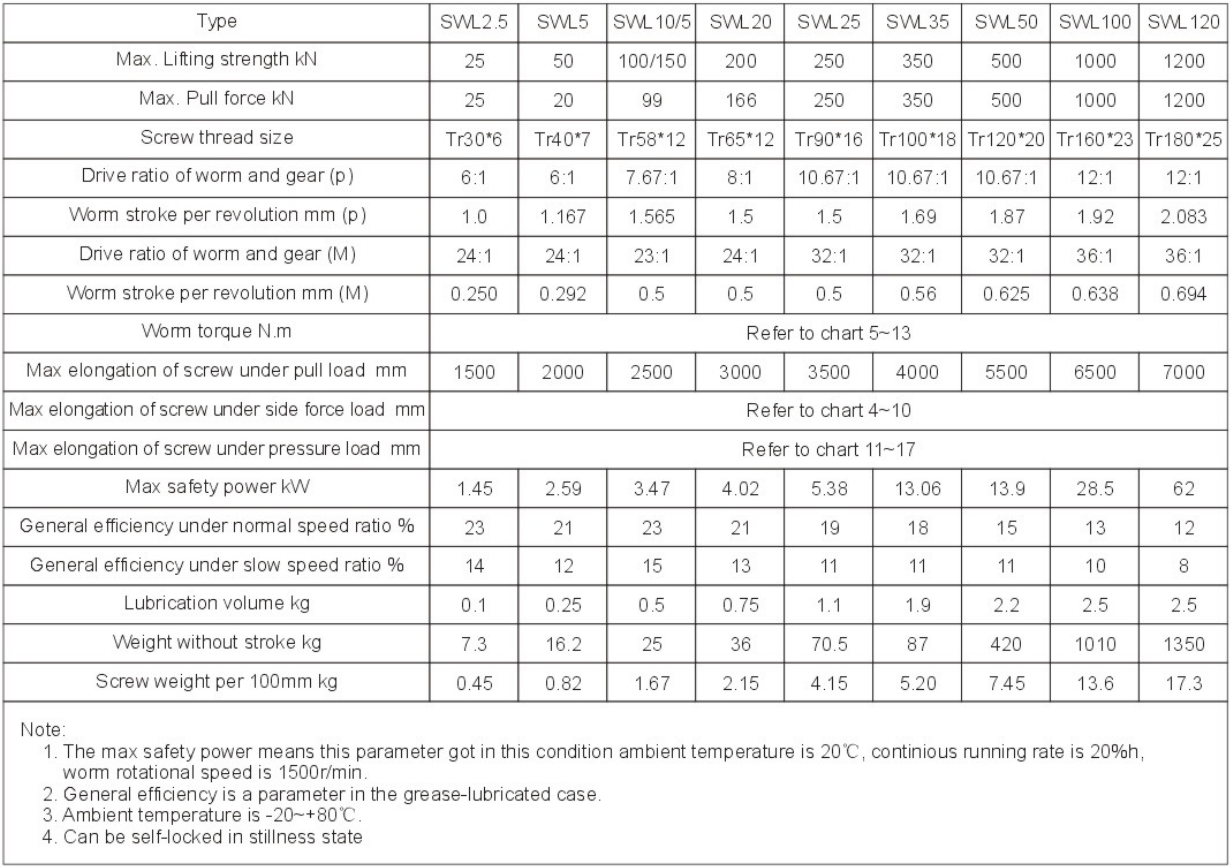

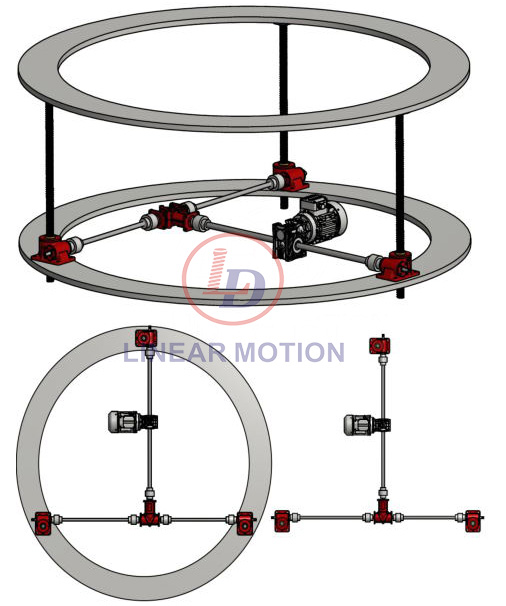

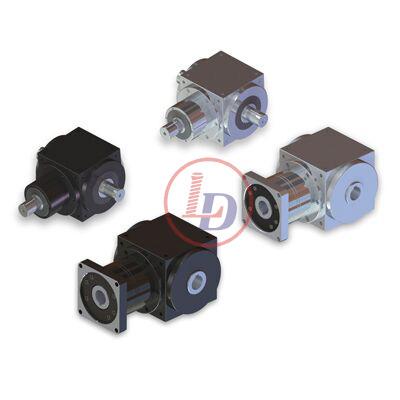

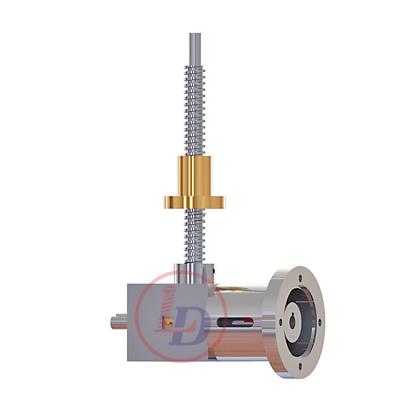

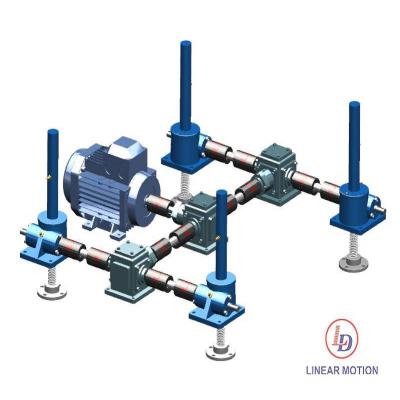

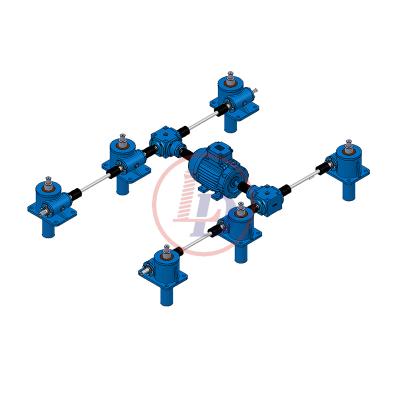

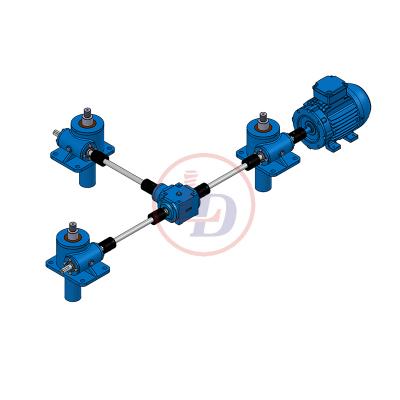

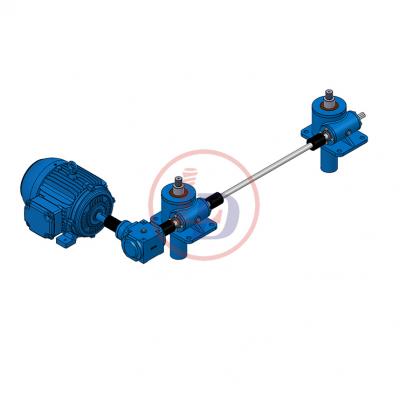

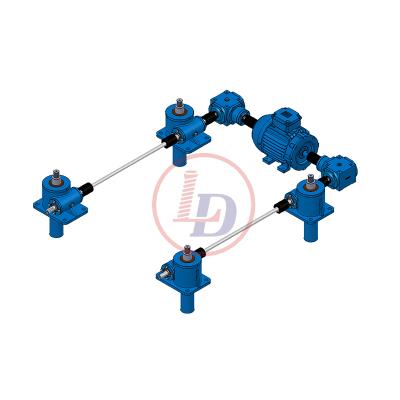

The ability to mechanically link multiple screw jacks together so that they move in unison is one of their greatest advantages. Typical arrangements involve screw jacks, bevel gear boxes, motors, reduction gearboxes, drive shafts, couplings and plummer blocks.

Screw Jack System Features:

1. Configuration: screw jacks, bevel gearboxes, connecting shaft, couplings, guides, electric motor etc.

2. Heavy duty, self-locking, positioning precision, uniform lifting speed, fully synchronization, easy installation, easy operation

3. Two screw jacks system, three screw jacks system, forty screw jacks system.

4. Extremely high capacity requirements of need very precise up or down control. It's of high mechanical, they are an excellent choice when hydraulic, pneumatic or chain systems are prohibitive choices.