Picture and Descriptions

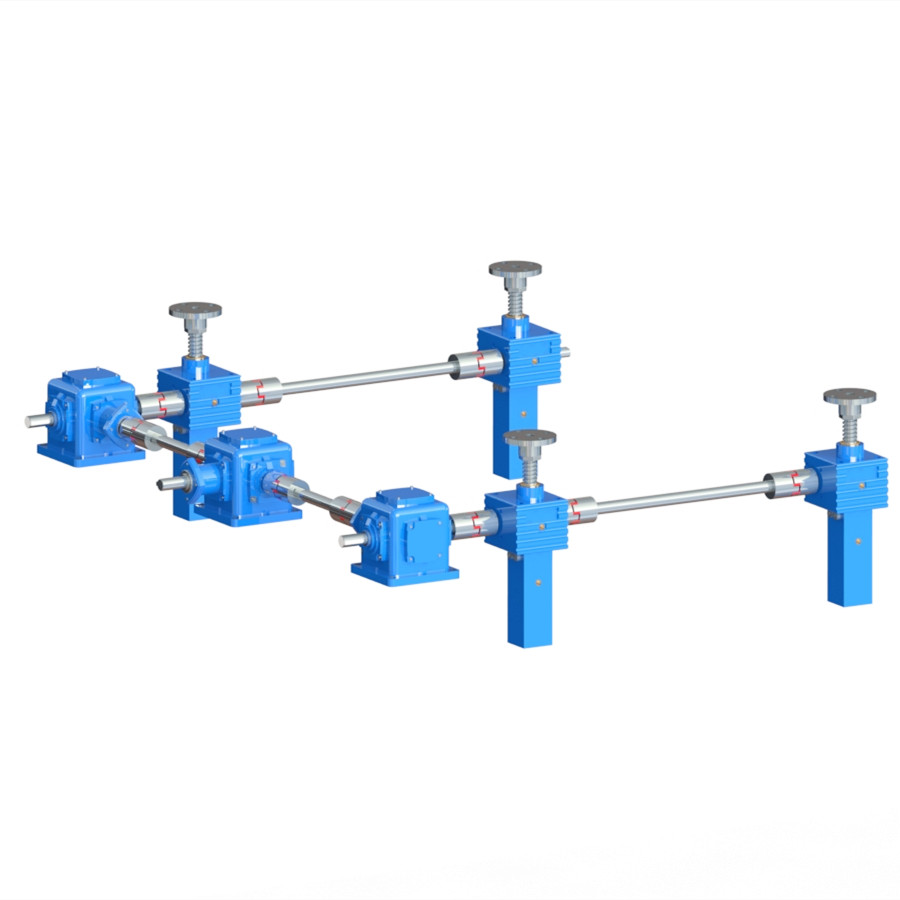

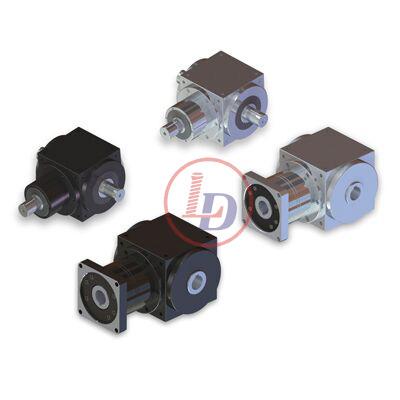

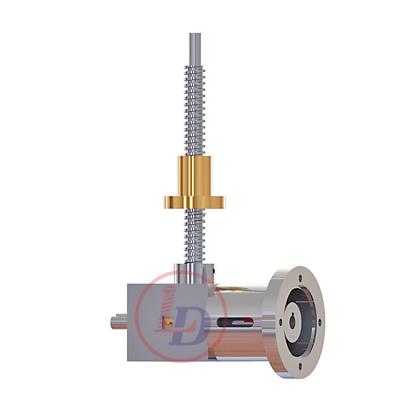

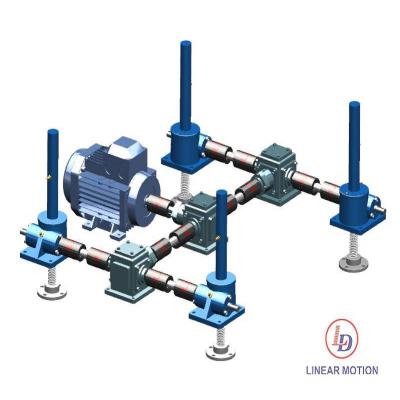

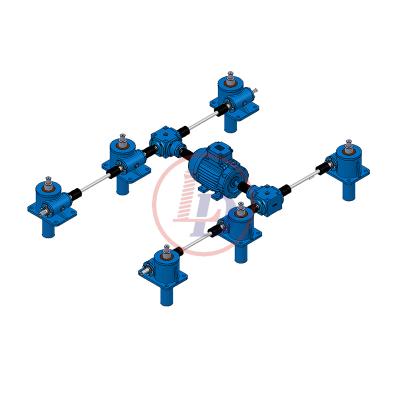

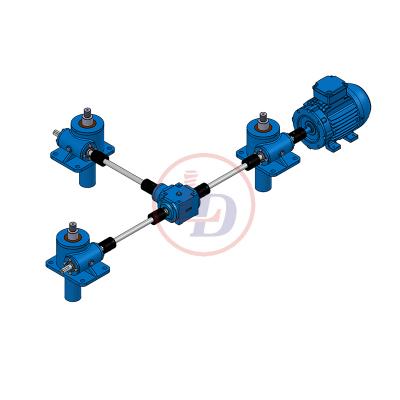

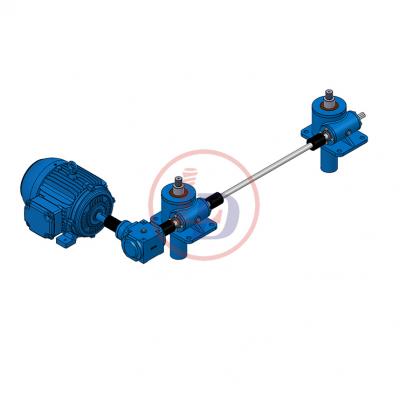

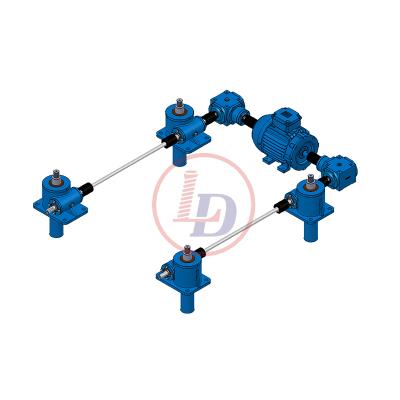

Screw jack lift system structures include miter gearboxes, screw jacks, electric motor or gear reducer, hand wheel, pillow block bearings, jaw couplings and line shafts.

Screw jacks system efficiency

When we choose multiple screw jack system,we should consider the efficiency.

The arrangement efficiency allows for misalignment due to slight deformation of the structure under load, for the losses in couplings and bearings, and for a normal amount of misalignment

in positioning the actuators and gear boxes. We use the following efficiencies (all standard units):

Two Worm Screw Actuator Arrangement - 95%

Three Worm Screw Actuator Arrangement - 90%

Four Worm Screw Actuator Arrangement - 85%

Six or Eight Worm Screw Actuator Arrangement - 80%

Notes: don't ignore bevel gearbox efficiency 98%

Screw jacks system Arrangement

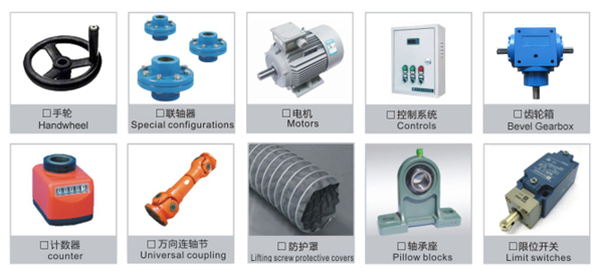

Screw Jack system Accessories

Screw Jack System Accessories include miter gear boxes, c-face motor adapters, limit switches, transducers, visual and digital position indicators, couplings, ball screws and ball screw systems, and locking rings.