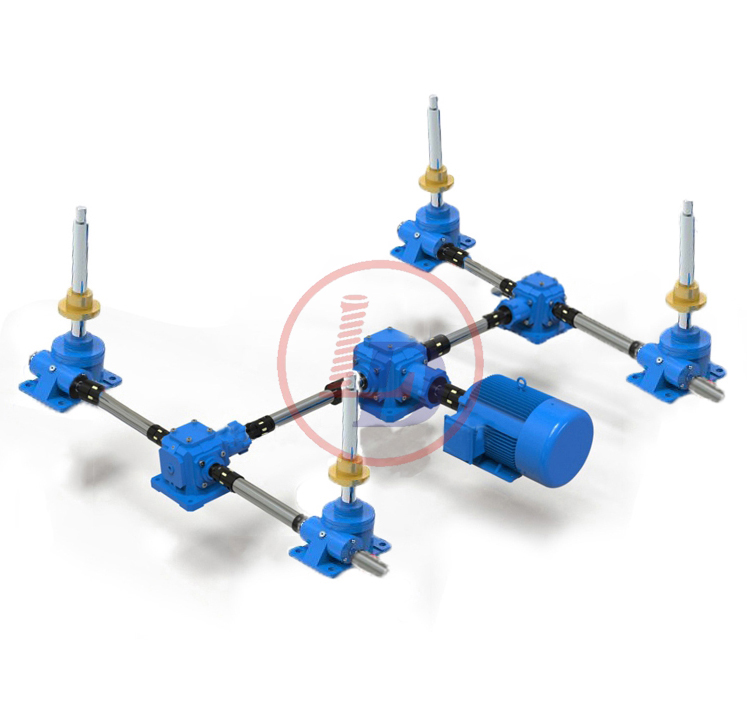

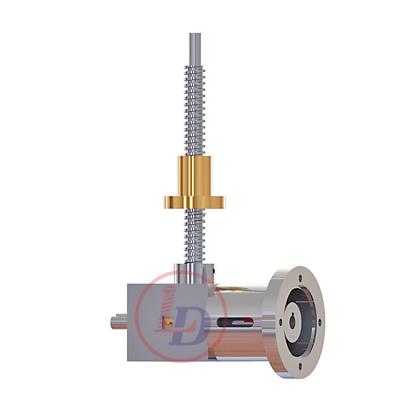

This design incorporates a lifting screw keyed to the worm gear as a single unit, forcing the lifting screw to rotate in the gearbox, but not translate. A traveling nut, running onthe rotating screw generates linear motion for the attached load. This type of jack is ideal for applications that cannot accommodate a screw protection tube.

For machine screw jacks-A key, fixed to the jack housing and inserted into a keyway milled into the length of the lifting screw forces the lifting screw to translate without rotating( The keyway in the screw causes greater than normal wear on the internal drive sleeve).For ball screw jacks-Anti-rotation is accomplished by a square guide attached to the screw translating inside a square stem cover attached to the jack.