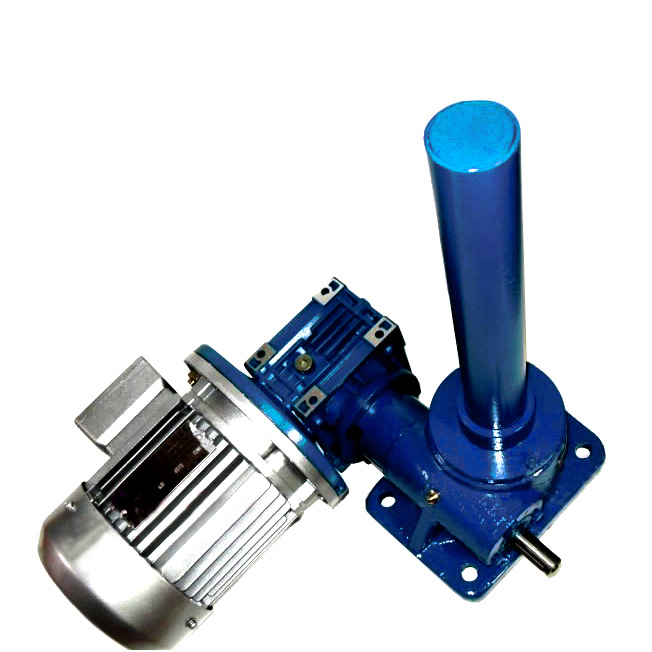

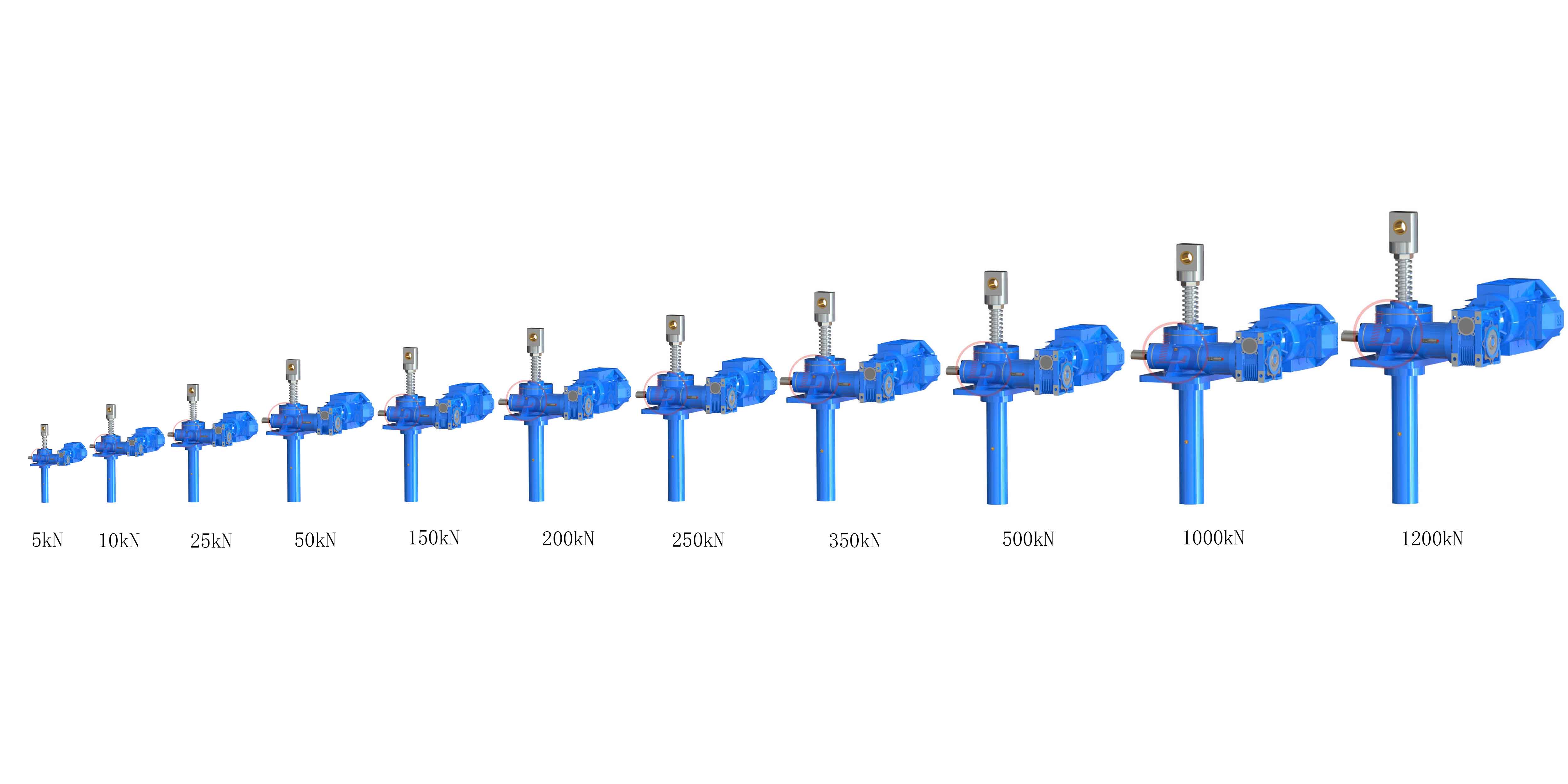

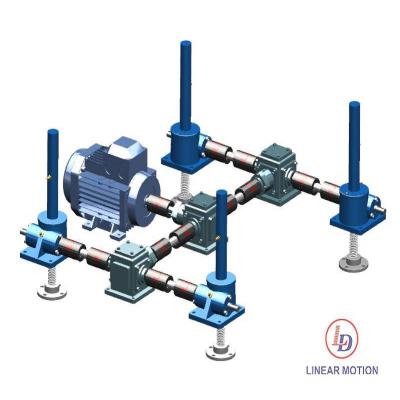

Screw jack is used in applications where linear motion is required. Lifting of any load, pushing or pulling of mechanical equipment, adjusting of tight clearances of mechanical parts can be done by screw jacks. Mechanical capacity of screw jacks is between 5kN and 2000kN. Jack screws can be used as linear motors, linear actuators, or mechanical lifts depending on type of motion.

Working Principle of Screw Jacks

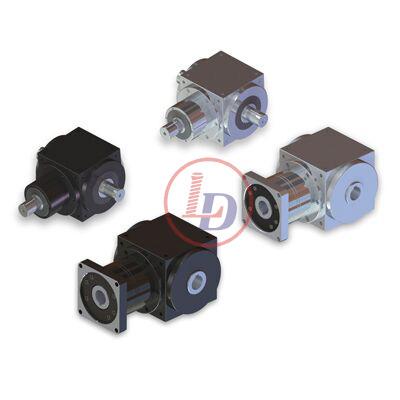

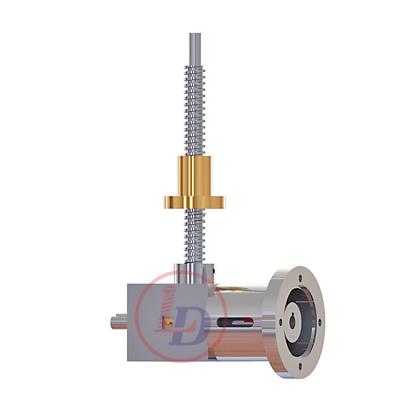

Main components of screw jacks are; trapezoidal lifting screw, worm screw, worm gear and gear housing. Worm screw is rotated manually or by motor. Worm gear is rotated by worm screw. The lifting screw moves through the rotating worm gear. The linear motion speed of lifting screw depends on thread size and rotation ratio of worm gears.