When selecting a screw-driven lifting mechanism for single-unit use, we generally add an anti-rotation structure. Why is this necessary?

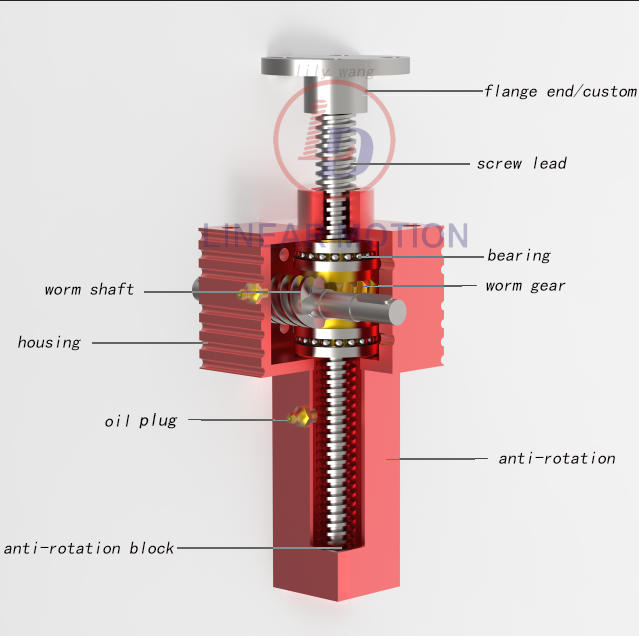

First, we need to understand the internal structure and working principle of a screw jack. A screw jack consists of a housing that encloses the internal worm gear transmission mechanism. The worm gear then engages with a trapezoidal screw, converting the rotational motion of the drive source into linear motion. The principle is that the worm gear meshes with the worm screw; the worm screw is driven by the power source to rotate, which in turn drives the worm gear to rotate. The worm gear then engages with the trapezoidal screw thread, and through sliding friction, achieves linear lifting and lowering.However, the friction between the worm gear and the screw can cause the screw to rotate. Therefore, when the load is not fixed, the load will rotate with the screw, preventing normal lifting and lowering. This is where an anti-rotation mechanism is needed to counteract the friction between the worm gear and the screw, ensuring that the screw only performs linear lifting and lowering motion, thus enabling the movement of the load.

Anti-rotation structures are used in many situations, most commonly when a single unit is used with an unfixed load. They are also needed in multi-unit systems where the lifting mechanisms are linked but the platform is only in contact with, not directly connected to, the lifting mechanisms. When encountering such situations, please inform us to prevent subsequent usability issues.

There are two types of anti-rotation structures: anti-rotation block and key way anti-rotation. The anti-rotation block method requires a square protective tube, which occupies part of the screw's travel length, thus requiring a longer screw. The key way anti-rotation structure is easier to manufacture and does not affect the screw's travel length, but it can cause some damage to the screw threads. Each structure has its advantages and disadvantages; anti-rotation block structures are generally used with ball screws, while key way anti-rotation structures are more common with trapezoidal screws.