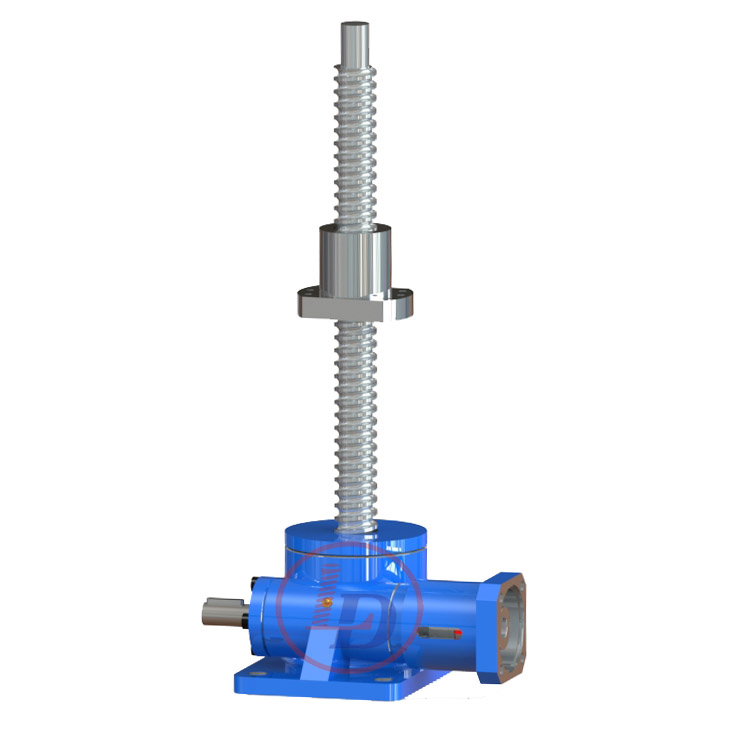

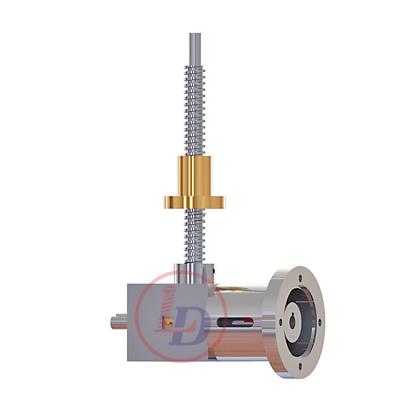

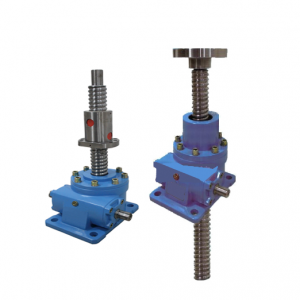

Worm gear Ball Screw Jacks use a ball screw and nut made from hardened alloy steel with bearing balls carrying the load between nut & screw.

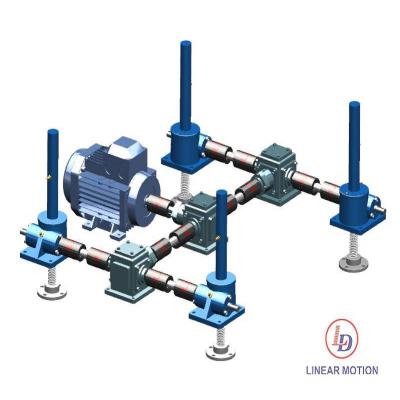

Ball Screw Jack are one of the most widely used mechanical actuator for intermittent duty cycles as the actuator incorporates a precision worm gear set in a rugged casting delivering positive, precise actuation.

Common screws slide on their threads and pull the connecting piece with them. This is how an ACME screw works. This sliding motion is easy to produce but extremely ineffiecient; around 40% of the input power is transferred to the work piece. To improve on this idea the sliding contact must be replaced with rolling elements. Ball Screws use ball bearings in the nuts to roll along the screw. The balls must recirculate or they will fall out of the nut. This leads to the current designs for recirculating ball screws that have efficiencies greater than 90%.

Main Parameters:

Maximal load: 147kN

Outerscrew diameter of : 55mm

Smallscrew diameter : 50mm

Pitch of screw: 43.1mm

Worm ratio(high speed):1:8

Amount of lift per revolution for ratio H: 1.5mm

Permissible output maximal power: 4.0kw(high speed)