Worm gear screw jacks are ideal option for various applications, such as lifting, lowering, tipping or moving. In each case, the different industries and the different power parameters require a powerful, reliable screw jack that is easy to adapt to the specific application, and to extend to a complete worm gear screw jack system. Now let's give you a brief introduction of worm gear screw jack.

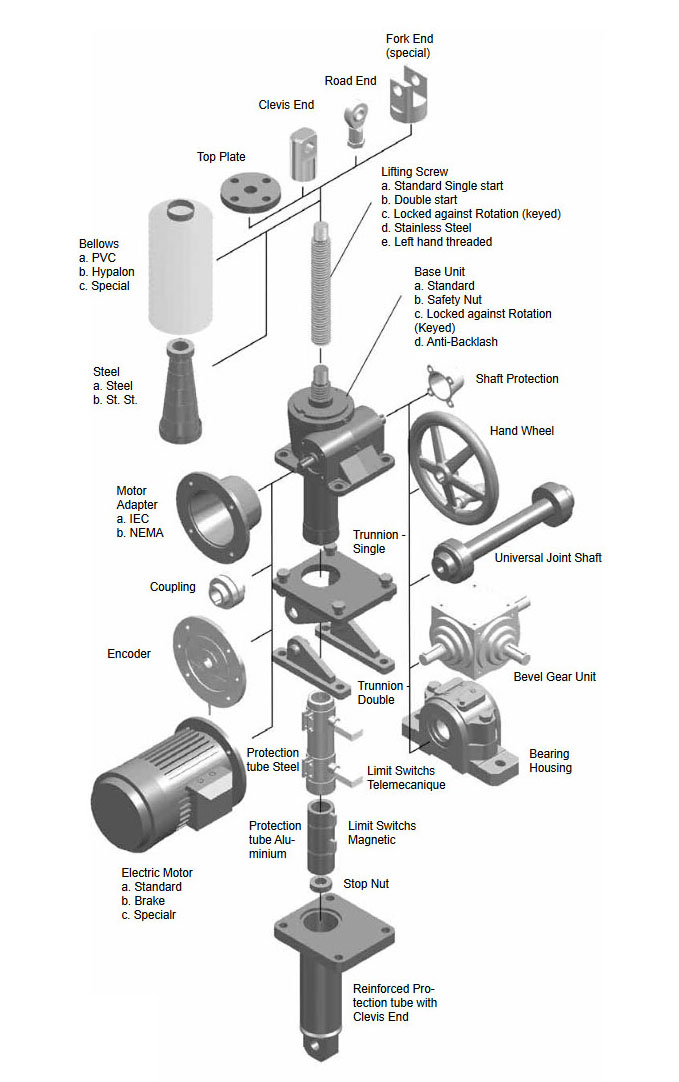

Structure diagram for screw jack:

Worm Gear Screw Jack systems are ruggedly designed and produced in standard models with load handling capacities from 1/4 ton to 100 tons. They may be used individually or in multiple arrangements. There are no "standard" travel lengths and all Worm Gear Screw Jack systems are built to specification.

The jack housings are made of ductile iron and proportioned to support the rated capacity of the unit. MJ, 1/4 ton, and 1/2 ton models have aluminum housings.

Worm Gear Screw Jack incorporates an alloy steel worm which drives a high strength bronze worm gear (drive sleeve). The worm shaft is supported on antifriction tapered roller bearings with external seals provided to prevent loss of lubrication (sealed radial bearings on the MJ, 1/4 , 1/2, and 1 ton units). The drive sleeve is supported on antifriction tapered roller or ball thrust bearings. Rotation of the drive sleeve causes the lifting screw to translate or rotate, depending upon jack configuration.

They can be driven by different motors: electrical, with either alternating or direct current, as well as hydraulic or pneumatic motors. Also they can be driven manually or with any other type of transmission.

Related products:

stainless steel worm gear screw Jacks