When to use Bevel Gear Jack?

Aug 05 , 2014

The most common classification of screw jack is trapezoidal and ball lift. Compared to these two types, the bevel gear screw jack are relatively less used, but it also has many advantages.Then what are the advantages of the bevel gear jack system? Let’s see the following.

Worm Gear Screw Jack includes acme screw jack and ball screw jack. Acme screw jack with self locking, low duty cycle, internal with grease lubrications; Ball screw jack without self locking, high duty cycle, high speed, long service lift, high precision with grease lubrications. Worm Gear Screw Jack structures include worm and worm gear set, bearing, grease seal, housing, spindle lifting screw. When multiple worm gear screw jacks lifting system, needs right angle miter boxes to transmit the power and torque to worm gear screw jacks.

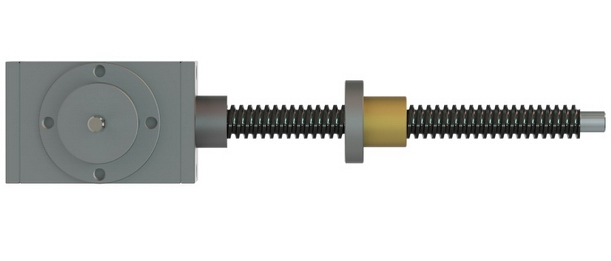

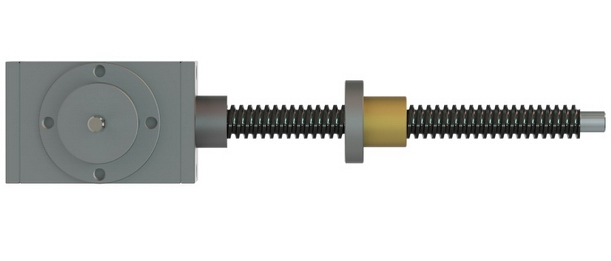

Bevel Gear Screw Jack with high speed, high duty cycle, internal with gear oil lubrications. Bevel Gear Screw Jack structures include pairs spiral bevel gear, drive shafts, bearing, grease seal, housing, spindle lifting screw. When multiple bevel gear screw jacks lifting system, don't need right angle miter boxes, bevel gear screw jacks are directly connected by connecting rods and couplings.

Hope the above information can help you to choose suitable screw jacks.