Slewing Drive Introduction

As the core component of turntable bearings, can withstand the axial load, radial load and overturning moment.

2. Structure

Slewing drive can be divided into two different structures as per different applications.

Light load slewing drive

Heavy load slewing drive

The dimensions of slewing drives include 3 inch, 5 inch, 7 inch, 9 inch, 12 inch, 14 inch, 17 inch, 21 inch and 25 inch.

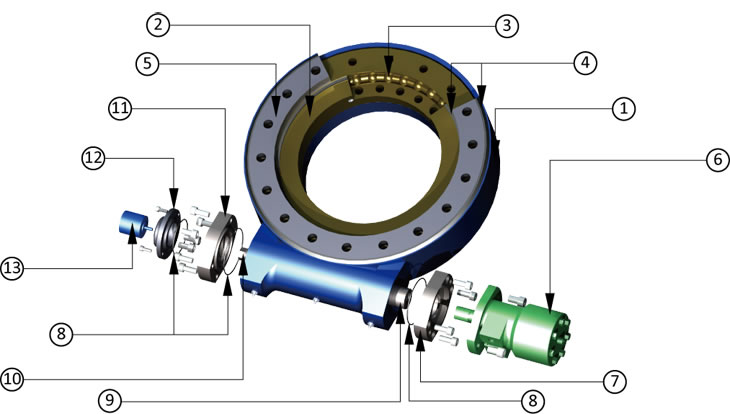

1.Housing, 2.Slewing ring,3.Raceway, 4.Seal ring, 5.Top plate, 6.Actuator (motor), 7.Motor adapter, 8.O-ring, 9.Worm input jack, 10.Non-input end of worm, 11.End cap, 12 Cover, 13 Encoder

3. Features:

Slewing drive is a special bearing. And a slewing drive usually consist of slewing bearing, worm shaft, housing, bearing, motor and so on. Motor drive the worm shaft, the outer ring of slewing bearing will rotate, the outer ring output the torque through flange while the inner ring of slewing bearing is fixed in housing.

Slewing Drive and rotary products, compared with the ease of installation, ease of maintenance, Installation space savings advantages to a greater extent.

4. Application:

Slewing drives are widely used in aerospace area, solar power systems, wind turbines, satellite broadcasting system, and engineering machinery like truck cranes, and man lifts, etc. Recently years, it has been prosperously used in photovoltaic power generation systems, special vehicle, heavy-duty flat-panel truck, container cranes, truck mounted crane, automobile crane and aerial vehicles, cranes, gantry cranes, small wind power stations, space communications, satellite receiver, etc.