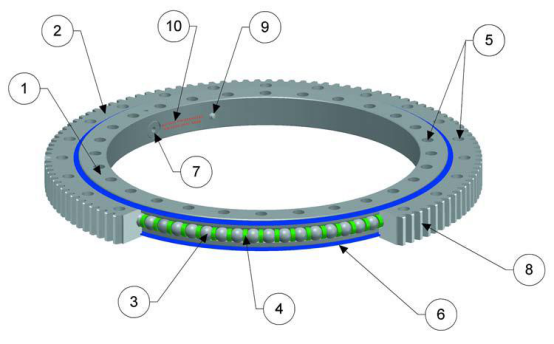

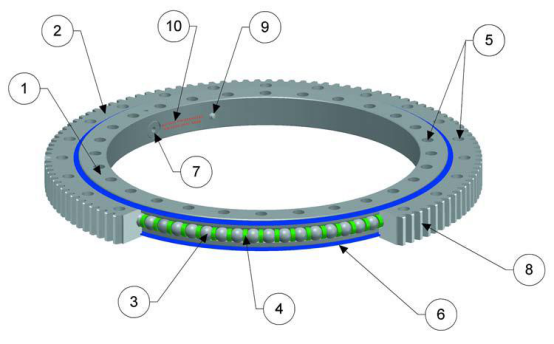

1, Internal ring

2, External ring

Slewing Ring consist of an internal and external ring with an integrated raceway system and optional internal or external teeth. The normal material is 50Mn.

3, Roller

In Slewing Rings, better rotation and loading transmission are achieved by special design and precision production of the rolling elements.

4, Spacer

Spacers separate the rolling elements and minimize friction and wear.

5, Mounting Holes

The force is transmitted to the mounting structure by bolts. Through holes or threaded holes can be provided in the inner and outer rings for these bolts.

6, Sealing

Polymer seals protect the Slewing Rings from normal dirt penetration, dust and loss of lubricant.

7, Plug hole

The rolling elements are inserted during manufacture through the filling plug hole, retained by the filling plug which is then secured by a pin.

8, Gear

Slewing Rings are designed with optional internal or external gear.

9, Grease nipple

Slewing Rings are designed for grease lubrication which is carried out via grease nipples.

10, ID

Bearing type and serial No.

Warning

●Mostly, a combination of axial, radial and tilting moment loads occur.

●Radial loading cannot exceed 10% of axis loading.

●Operating temperature on Slewing Ring in range from -20°C to +60°C

●Fasten the bolts alternately

●Lubricate regularly

●Check bolts and ensure proper retightening load