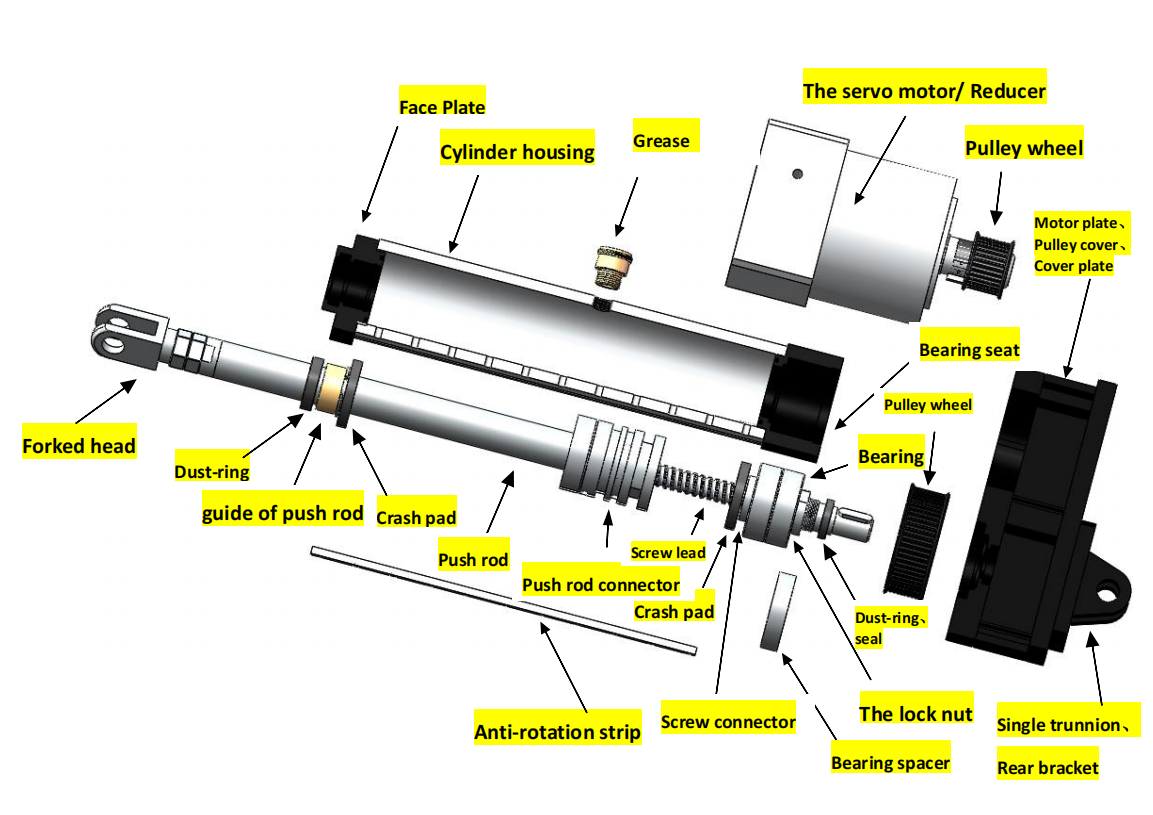

Before choosing a servo electric cylinder, we must first understand its structure.

First is the support section, mainly composed of the cylinder body, pulley box, bearings, and other structures. The main function of this part is to support the transmission structure, connect with the on-site equipment, and fix the overall structure of the servo cylinder to facilitate its installation and use.

The second part is the transmission section, mainly composed of ball screws, ball nuts, synchronous belts or gears. The function of this part is to convert the rotational motion of the servo motor into linear motion. The ball screw can be processed by rolling and grinding processes, and the accuracy level can reach C5.

The third part is the sealing section, mainly composed of sealing rings and other structures, which provides sealing and reduces dust entry into the cylinder body, thereby reducing maintenance costs. Compared with hydraulic systems, it only requires regular replacement or addition of lubricating grease for maintenance.

Finally, there is the drive source and accessory structure. The drive source can be a servo motor, DC motor, or stepper motor, to achieve high-efficiency and high-precision control. Other optional accessories include limit switches, displacement sensors, pressure sensors, etc. Multiple accessories work together to achieve high-speed and high-precision linear motion.

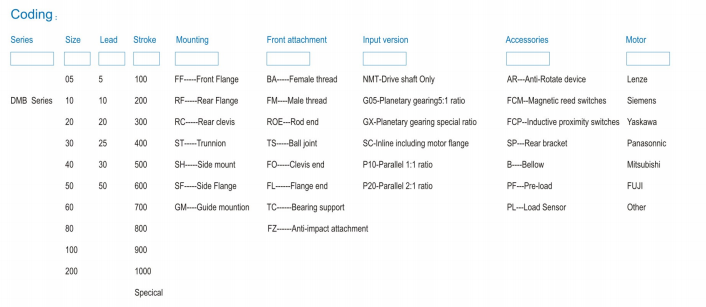

For servo cylinder selection, we must first understand the customer's operating conditions. The main factors include load, speed, stroke, operating frequency, mounting type, motor type, accuracy, and accessory requirements.

Step 1: Knowing the customer's load and stroke, we can find the smallest servo cylinder model that meets the requirements using the stability curve diagram in the selection catalog.

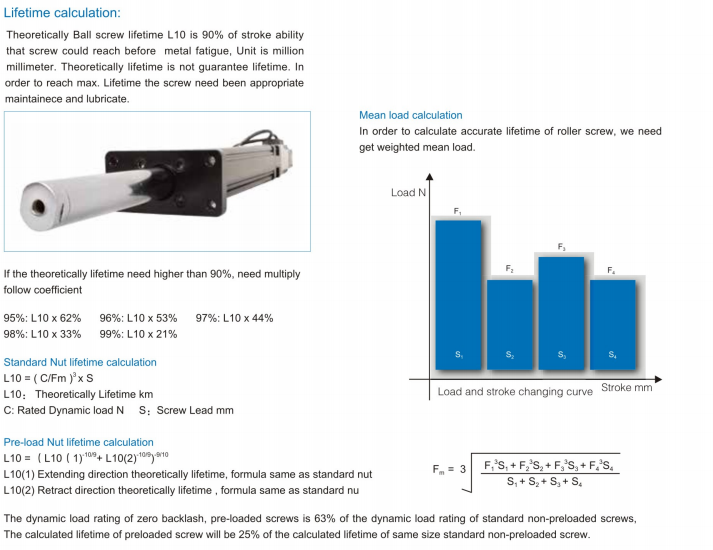

Step 2: Based on the customer's operating frequency requirements, calculate the travel distance of the ball screw for that model, and calculate the ratio of the theoretical distance to the actual distance to determine if it meets the 5-year service life (normal working environment). If not, the servo cylinder model needs to be increased until the service life meets the requirements.

Step 3: Based on the customer's speed requirements, calculate the power and torque required to drive the load of the servo cylinder, and match the corresponding gearbox speed ratio.

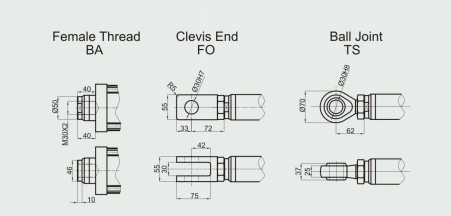

Step 4: Determine the specific mounting type of the servo cylinder and the selection of the ball screw based on the mounting type and accuracy requirements. Servo cylinders come in various mounting configurations, including front flange (FF), rear flange (RF), rear clevis (RC), side trunnion (ST), and side flange (SF). Ball screws are manufactured through rolling or grinding; ground ball screws have longer lead times but offer higher precision.

Finally, the motor type, communication mode, driver type, voltage, cable length, etc., are determined. Accessory structures include magnetic proximity switches (FCM), proximity limit switches (FCP), dust covers (B), pressure sensors, displacement sensors, anti-rotation mechanisms, and various other structures. With all these steps completed, the selection of a complete servo cylinder is finished.