The customer from Thailand order the SJA50 cuibic housing screw jack with 1.5 kW motor.

This is the parameters for SJA50.

| Size | SJA5 | SJA10 | SJA20 | SJA50 | SJA80 | SJA100 | ||||||

| Max lifting load [kN] | 5 | 10 | 20 | 50 | 80 | 100 | ||||||

| Screw dia x pitch [mm] | Tr18x4 | Tr20×4 | Tr30×6 | Tr40×7 | Tr50x8 | Tr60×9 | ||||||

| Warm ratio | V1 | 1:4 | 1:4 | 1:6 | 1:7 | 1:8 | 1:8 | |||||

| L1 | 1:16 | 1:16 | 1:24 | 1:28 | 1:32 | 1:32 | ||||||

|

Stroke for one input turn [mm] |

V1 | 1 | 1 | 1 | 1 | 1 | 1.125 | |||||

| L1 | 0.25 | 0.25 | 0.25 | 0.25 | 0.25 | 0.281 | ||||||

|

Max input power [kW] |

V1 | 0.30 | 0.57 | 1.14 | 2.2 | 2.5 | 3 | |||||

| L1 | 0.15 | 0.27 | 0.55 | 1.1 | 1.5 | 2.2 | ||||||

|

Max starting torque at full load[Nm] |

V1 | 4.2 | 8 | 18 | 48.5 | 75 | 100 | |||||

| L1 | 1.5 | 3.1 | 6.7 | 20 | 30 | 41 | ||||||

| Starting efficiency | V1 | 0.24 | 0.25 | 0.19 | 0.18 | 0.17 | 0.18 | |||||

| L1 | 0.16 | 0.16 | 0.12 | 0.11 | 0.10 | 0.11 | ||||||

|

Running efficiency at 1500mm |

V1 | 0.34 | 0.35 | 0.33 | 0.32 | 0.31 | 0.33 | |||||

| L1 | 0.25 | 0.25 | 0.24 | 0.23 | 0.22 | 0.23 | ||||||

|

Torque without load[Nm] |

V1 | 0.11 | 0.29 | 0.40 | 0.84 | 1.85 | 2.1 | |||||

| L1 | 0.09 | 0.18 | 0.29 | 0.59 | 1.12 | 1.4 | ||||||

| Housing material | Spheroidal graphite iron | |||||||||||

| Weight[kg] | 3.2 | 5 | 8.5 | 21.5 | 36 | 58 | ||||||

|

Weight per 100mm screw &protective tube[kg] |

0.36 | 0.50 | 0.75 | 1.52 | 2.44 | 3.02 | ||||||

| Size | SJA200 | SJA300 | SJA450 | SJA700 | SJA1000 | |||||||

| Max lifting load [kN] | 200 | 300 | 450 | 700 | 1000 | |||||||

| Screw dia x pitch [mm] | Tr80x 12 | Tr100×16 | Tr120×16 | Tr140×20 | Tr160x20 | |||||||

| Warm ratio | V1 | 1:8:7.5 | 1:10.25 | 1:10.75 | 1:13.33 | 1:13.33 | ||||||

| L1 | 1:35 | 1:41 | 1:43 | 1:40 | 1:40 | |||||||

|

Stroke for one input turn [mm] |

V1 | 1.371 | 1.56 | 1.49 | 1.5 | 1.5 | ||||||

| L1 | 0.343 | 0.39 | 0.37 | 0.5 | 0.5 | |||||||

|

Max input power [kW] |

V1 | 4 | 7 | 11.5 | 18.5 | 22 | ||||||

| L1 | 3.5 | 5.5 | 5.5 | 7.5 | 9.5 | |||||||

|

Max starting torpue at full load[Nm] |

V1 | 265 | 460 | 675 | 1050 | 1620 | ||||||

| L1 | 106 | 180 | 275 | 510 | 820 | |||||||

| Starting efficiency | V1 | 0.17 | 0.18 | 0.16 | 0.16 | 0.15 | ||||||

| L1 | 0.11 | 0.12 | 0.10 | 0.11 | 0.10 | |||||||

|

Running efficiency at 1500mm |

V1 | 0.33 | 0.33 | 0.30 | 0.31 | 0.29 | ||||||

| L1 | 0.22 | 0.23 | 0.20 | 0.21 | 0.19 | |||||||

|

Torque without load[Nm] |

V1 | 2.8 | 3.8 | 5.5 | 8.5 | 11 | ||||||

| L1 | 2.1 | 3.1 | 4.5 | 5.5 | 7.5 | |||||||

| Housing material | Spheroidal graphite iron | cast steel | ||||||||||

| Weight[kg] | 75 | 110 | 200 | 400 | 800 | |||||||

|

Weight per 100mm screw &protective tube[kg] |

4.5 | 6.8 | 9.0 | 12.5 | 16.5 | |||||||

Acme screw with two or three start threads are available.

Selection Guide:

■Cautions for choosing the model type ofthe screw jack.The percentage of the duty cycle wihin 10 minutes: SJA series acme screw jack: 30%. Ball screw and satellite roller screw jack: 50%.The duty cycle can be increased if the actual load is less than the rated loads, please consult with the engineers of Lude Transmission for the specifics,

■The maximum input running speed:1800rpm

■If the actual load is above 25% and less than 100%(inclusive) of the full load,the required input torque=load ratio x torque at full load.

■For the stroke exceeding 300mm, the stabity should be checked, please refer to the chart reflecing the relationship between the load and the stroke.

■Adjust the safety coefficient according to the load, 1.0-1.2 for the even load; 1.3-1.5 for the moderate load;1.6-2.5 for the heavy load.

■For the normal perfomance, the input power should not exceed the max. input power, input power=(torque at full load x load ratio x input speed RPM)/9550

■The working temperature affects the max. input power. Actual max. iput power=rated max. input power x the temperature coefficient. The temperature coefficent varies in terms of the temperature: -10℃-25℃ temperature coefficient=1,30℃ temperature coefficient=0.85,40℃ temperature coefficient=0.65

■For the application of synchronous lifting platform,the combination coefficient shoud be considered, the losing of combination shoud also be reckoned in calculating the total power.

The combination coeffcient varies according to the quantity of screw jacks in the synchronous platform: For 2 PCS screw jack in a platform,the combination coefficient is 0.95, For 3 PCS screw jack in a platform, the combination coefficient is 0.9, For 4 PCS screw jack in a platform, the combination coefficient is 0.85, For 6-8 PCS screw jack in a platform, the combination coefficient is 0.8, it is recommended to increase the combination coefficients appropriately if the double clevis mounting of the screw jack is adopted

■The acme screw jack wih big ratio possess the self-locking function,whie that with small ratio has uncertain self-locking, the brake needs to be equipped in the safey and vibrating application.(situation)

■The axial error of the acme and ball screw jack with the stroke of 300mm is 0.1 mm, while that of the screw jack equipped with anti-backlash fixings is 0.02mm.

■To avoid the lateral load,the guide device can be used to offset the lateral load.

■The catalogue only lis the parameters and dimensions of he acme screw jack,as for the parameters and dimensions of the ball screw jack,please consut with Lude engineer.

■For non-standard screw jack,please consult with Lude engineer.

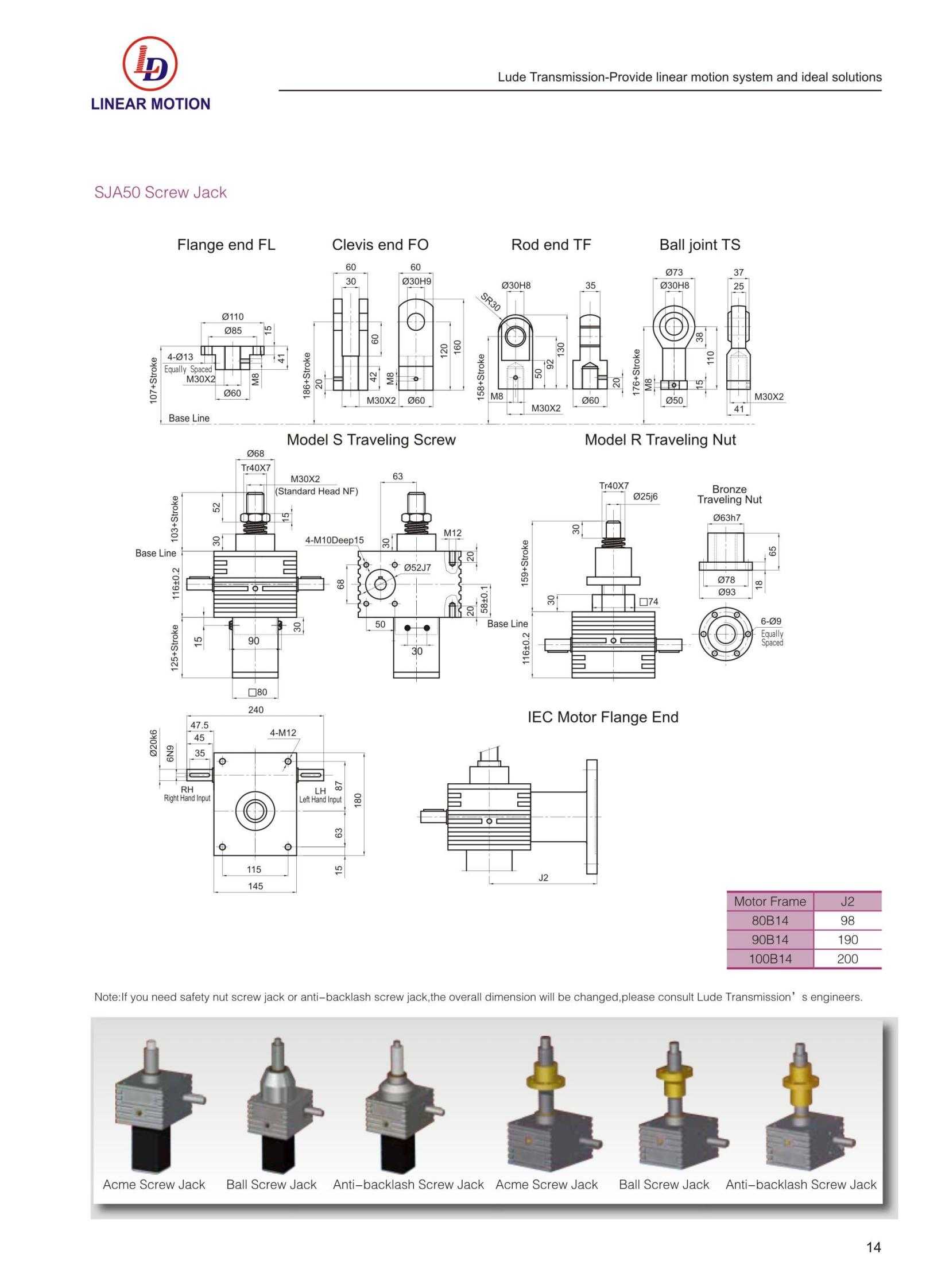

This is the drawing of SJA50 for your reference.

When finishing the production, we well pack the screw jack and ship it to our customer.

The customer received the package and he has praised our product.