Compared with some other types of jack,the Worm gear machine screw jack has an important advantage that is it is self-locking, which means when the rotational force on the screw is removed, it will remain motionless where it was left and will not rotate backwards, regardless of how much load it is supporting. This makes them safer than the hydraulic jack itself, for example, if the force on the hydraulic actuator is released accidentally, it will move backwards under load.

Then what is "self-locking"? Let us see the following information.

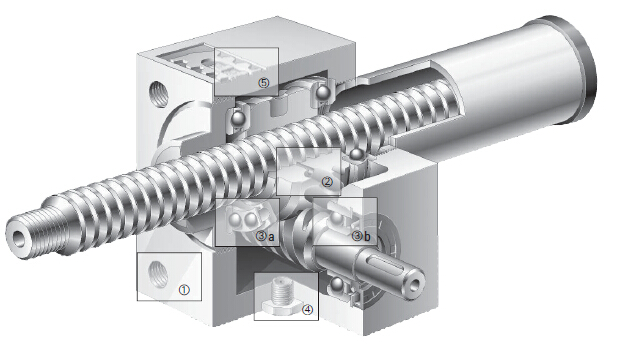

Large frictional forces cause most screws in practical use to be "self-locking", also called "non-reciprocal" or "non-overhauling". This means that applying a torque to the shaft will cause it to turn, but no amount of axial load force against the shaft will cause it to turn back the other way, even if the applied torque is zero. This is in contrast to some other simple machines which are "reciprocal" or "non locking" which means if the load force is great enough they will move backwards or "overhaul". Thus, the machine can be used in either direction. For example, in a lever, if the force on the load end is too large it will move backwards, doing work on the applied force. Most screws are designed to be self-locking, and in the absence of torque on the shaft will stay at whatever position they are left. However, some screw mechanisms with a large enough pitch and good lubrication are not self-locking and will overhaul, and a very few, such as a push drill, use the screw in this "backwards" sense, applying axial force to the shaft to turn the screw.

A push drill, one of the very few mechanisms that use a screw in the "backwards" sense, to convert linear motion to rotational motion. It has helical screw threads with a very large pitch along the central shaft. When the handle is pushed down, the shaft slides into pawls in the tubular stem, turning the bit. Most screws are "self locking" and axial force on the shaft will not turn the screw.

This self-locking property is one reason for the very large use of the screw in threaded fasteners such as wood screws, sheet metal screws, studs and bolts. Tightening the fastener by turning it puts compression force on the materials or parts being fastened together, but no amount of force from the parts will cause the screw to untighten. This property is also the basis for the use of screws in screw top container lids, vises, C-clamps, and screw jack lifts. A heavy object can be raised by turning the jack shaft, but when the shaft is released it will stay at whatever height it is raised to.

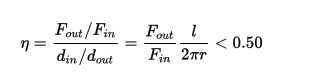

A screw will be self-locking if and only if its efficiency η is below 50%.

Whether a screw is self-locking ultimately depends on the pitch angle and the coefficient of friction of the threads; very well-lubricated, low friction threads with a large enough pitch may "overhaul".

Now come back to screw jacks. In the case of large shocks, the self-locking function of the lift may be invalidated. Worm gear screw lift self-locking function depends on the following parameters:

• The size of the lead

• Different gear ratios

• Lubrication

• Friction coefficient

• Environmental effects such as high or low temperature, vibration, etc.

• Installation location

Ball screw type and large pitch of the trapezoidal screw series without self-locking function. Therefore, in these cases must use the appropriate brake or brake motor. For smaller guides

(Single line), providing a limited self-locking function. Self-locking function depends on the specific situation.

Learn more about self-locking screw jacks at www.ludetransmission.com