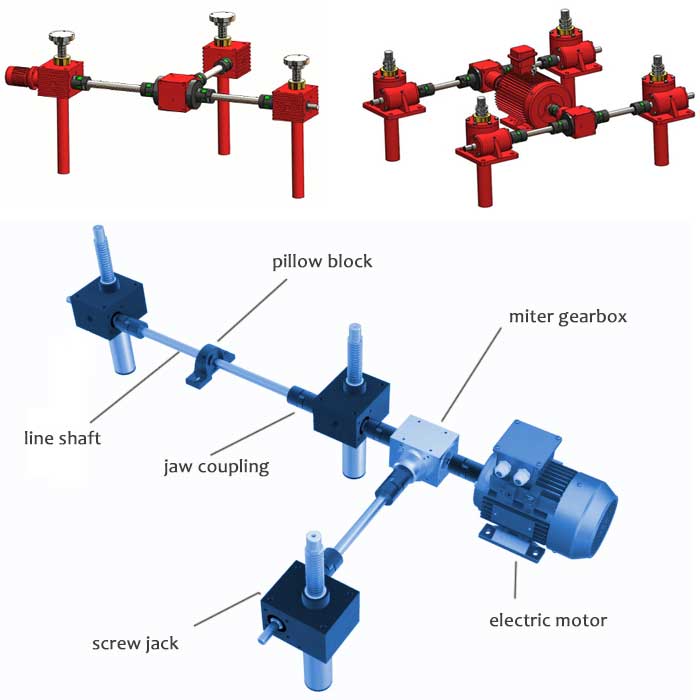

Screw jack lift system structures include miter gearboxes, screw jacks, electric motor or gear reducer, hand wheel,pillow block bearings, jaw couplings and line shaftings.

Screw Jack System Features:

1. Heavy duty, self-locking, positioning precision, uniform lifting speed, fully synchronization,

easy installation, easy operation

2. Two screw jacks system, three screw jacks system..forty screw jacks system.

3. Extremely high capacity requirements of need very precise up or down control.

It's of high mechanical, they are an excellent choice when hydraulic, pneumatic or chain systems

are prohibitive choices.

4. Widely used in wood working machines, plastics processing machines, textile machines,

assembly equipment in the automobile and aircraft industries, food and beverage production

equipment as well as packaging machines.

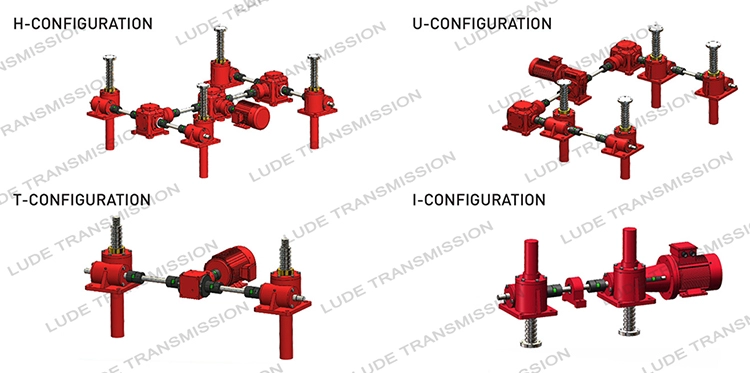

Four of the most popular system configurations are the ‘H’, ‘U’, “T” and “I” configured jacking systems. Note that multiple screw jacks can be linked together mechanically or electrically. The latter is useful if there is no space for linking drive shafts.

Screw jack systems are not limited to the number of screw jacks shown here. They are regularly supplied to clients with 2,3, 4, 6,8 jack systems. Larger systems can extend up to 16 or higher.

With the use of electronic synchronisation/control multiple systems or screw jacks can be used in unison.