According to movement type, the worm gear screw jack can be classified to translating screw jack and rotating screw jack. Then how do these two types of screw jacks work?Let’s see the followings.

---Translating screw jack

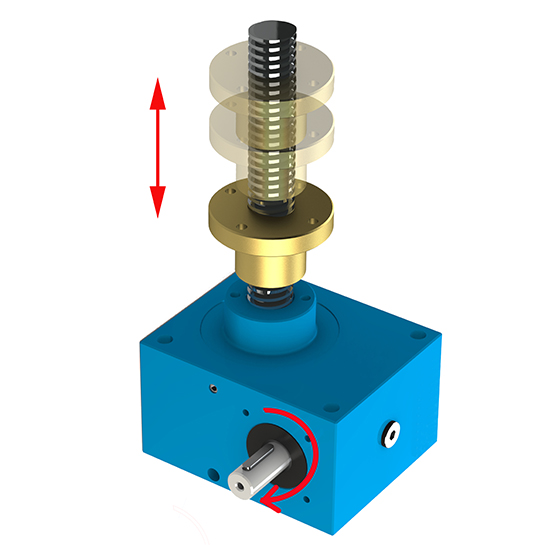

The rotation of the worm shaft causes the worm gear to rotate. For translating screw jacks

the worm gear is threaded to accommodate the lead screw thread. As the worm gear turns,

the friction forces on the screw thread act to turn the screw also. The greater the load on the

screw jack unit, the greater the tendency of the screw to turn. If the screw turns with the nut

(worm gear), it will not raise the load. In those cases where a single unit is used, and where the

load cannot be restrained from turning, it is necessary to use a screw jack with an anti-rotation

mechanism (anti-rotation keyed screw jack). Lead screw key torque must be checked as excessively heavy unguided loads could break the anti-rotation mechanism.

---Rotating Screw Jack

The rotation of the worm shaft causes the worm gear to rotate. For rotating screw jacks the lead

screw is fixed to the worm gear and they rotate at the same speed. As the worm gear turns, the

friction forces on the screw thread act to turn the nut also. The greater the load on the screw

jack unit, the greater the tendency of the nut to turn. If the nut turns with the screw, it will

not raise the load. Therefore the nut needs to be fixed to a structure to prevent rotation.

When choosing translating screw jacks, the available screw top end can be top plate,threaded end,plain end,clevis end,fork end.But for rotating screw jack,the available screw top end can only be plain end and threaded end.