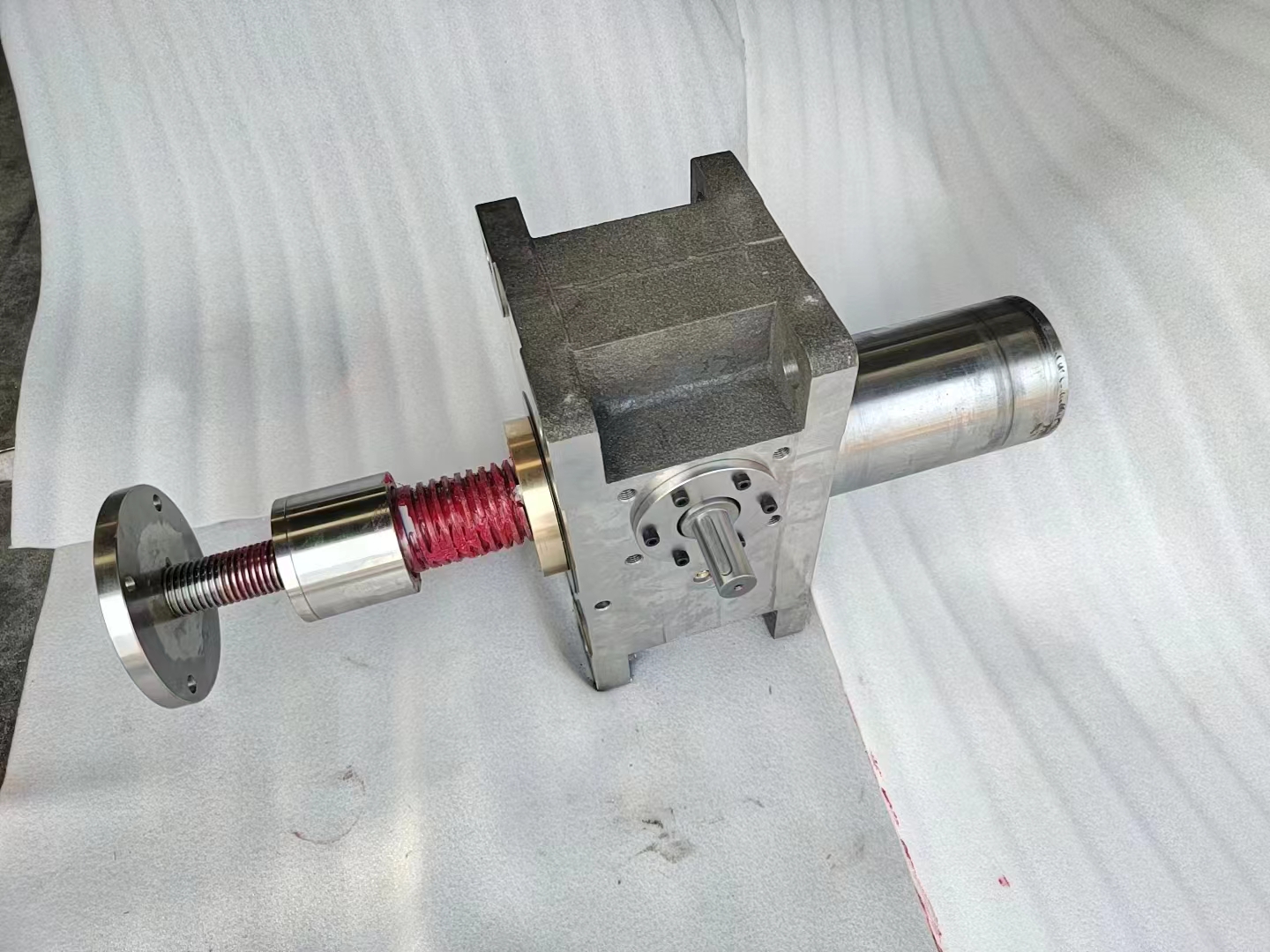

The double-section screw structure consists of two screws and two nuts. The diameter of the first-stage screw is larger than that of the second-stage screw. There is a keyway on the first-stage screw, and the inner hole of the worm gear is a through hole with a keyway. When the worm gear rotates counterclockwise, the key structure drives the first-stage screw to rotate. A nut with an internal thread is installed above the turbine and fixed on the top of the box. It cooperates with the thread of the first-stage screw. The screw and the nut produce relative movement, and the screw rises or falls. The second-stage structure is also a combination of a pair of nuts and screws. The secondary nut is connected to the primary screw and rotates and rises and falls with the primary screw. The secondary screw is connected to the user's equipment. The screw does not rotate, but only rises and falls.

1. The primary and secondary screws have the same axis;

2. Compact structure, small size, saving space and cost;

3. Reduce the weight of the overall platform, reduce the output power of the drive source, energy saving and environmental protection;

4. Double the speed. Compared with a single-section screw, the speed is twice that of a single-section screw at the same input speed;