The design principle of worm gear screw jack

The design principle of the worm gear screw jack is mainly based on the principle of spindle transmission and worm gear transmission. The following is a detailed summary:

1. Principle of spindle transmission

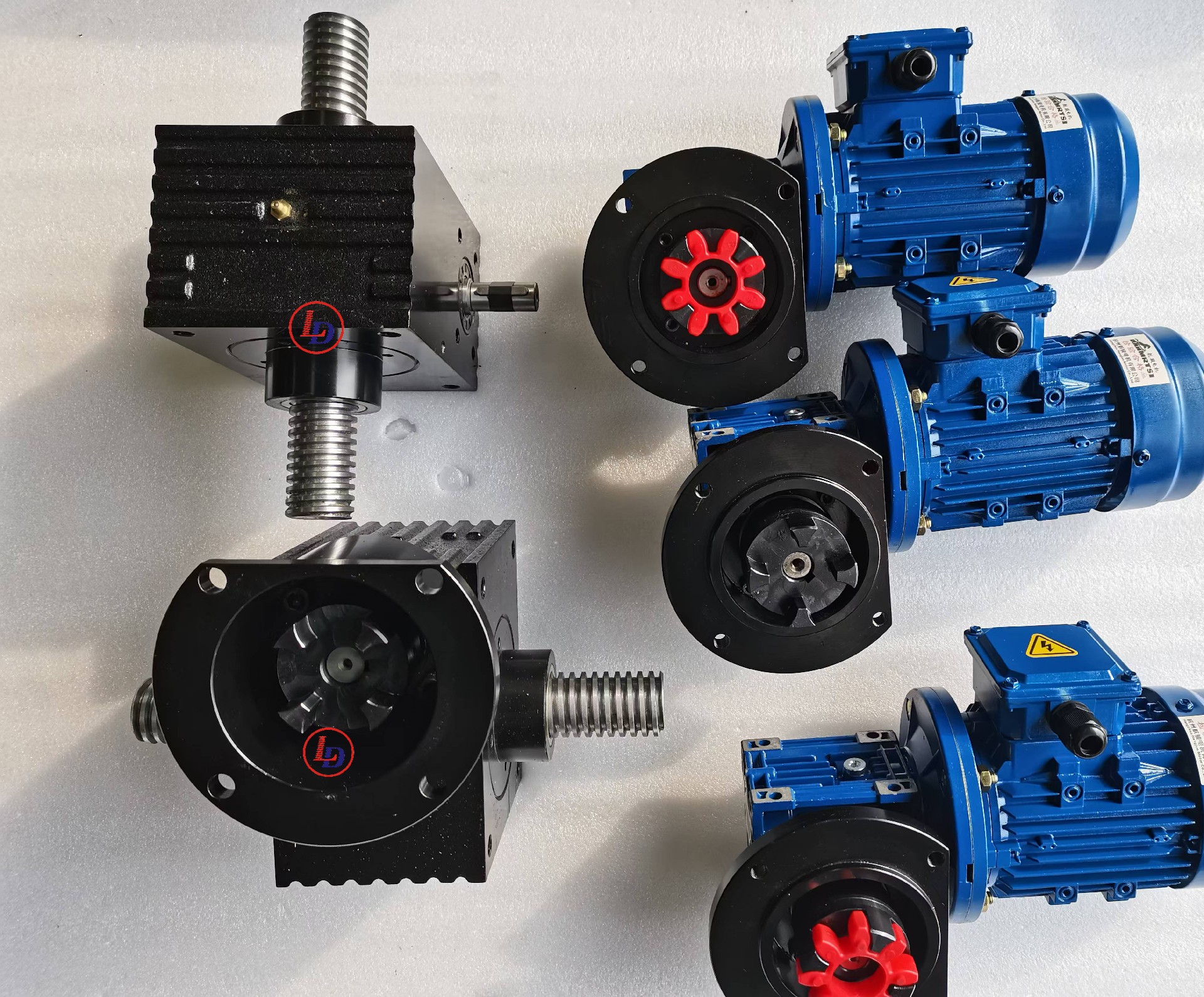

The core component of the worm gear screw jack is the spindle (or lead screw), which is a flat belt-like structure (or cylindrical structure) in a spiral shape, fixed at the center of the equipment by a worm gear. The twisted shape of the spindle enables the object to maintain a stable balance during movement, avoiding tilting or shaking. At the same time, the flat structure (or cylindrical structure) of the spindle also enables the object to remain horizontal while being transported vertically, ensuring the safety of the transportation process. When the worm gear screw jack starts working, the transmission device will drive the worm gear to rotate, and then the spindle (or lead screw) will drive the carried object to rise or fall.

2. Worm gear transmission principle

Another key principle of the left and right screw jack is the worm gear transmission. The worm gear is the core transmission component of the screw jack, which achieves power transmission and deceleration through mutual meshing. The worm shaft is driven to rotate by a motor or manually, which in turn drives the worm gear to rotate at a slower speed. This design not only achieves effective power transmission, but also amplifies the thrust through the deceleration effect of the worm gear, making the lifting process smoother and more powerful.

Specifically, the inner cavity of the worm gear is processed into an internal thread, which matches the external thread on the screw to form a spindle transmission. As the worm gear rotates, the screw will move up and down along the axis, thereby driving the lifting platform to achieve lifting motion. Due to the deceleration effect of the worm gear, the moving speed of the screw is effectively slowed down, thereby amplifying the thrust and making the lifting process smoother and more powerful.

3. Left-right rotation design

The left-right rotation design of the screw jack is mainly achieved by changing the rotation direction of the worm gear and worm shaft. When the motor or manual drive worm gear rotates, by changing the rotation direction of the motor or manual operation, the worm gear can rotate in different directions, and then drive the lead screw to move in different directions, realizing the left-right rotation lifting function of the lifting platform.

4. Other key components

In addition to the spindle and worm gear, the left-right rotating screw jack also contains other key components, such as the housing, bearings, etc. The housing is the outer shell of the screw jack, which protects the internal transmission components and prevents them from being damaged by external factors such as dust and impurities. At the same time, the housing also has a certain load-bearing capacity to ensure stability during the lifting process. The bearings are installed on rotating parts such as worm shafts, worm gears and lead screws, which reduces the friction and wear between them and improves the transmission efficiency and service life.

In summary, the design principle of the left-right rotating screw jack is mainly based on the principles of spindle transmission and worm gear transmission. The left-right rotating lifting function of the lifting platform is realized by changing the rotation direction of the worm gear and spindle. At the same time, the left-right rotating screw jack also contains other key components such as the housing, bearings, etc., which jointly ensure the stability and safety of the lifting process.