The Electric linear actuator is a good choice when you need simple, safe and clean movement with accurate and smooth motion control. You may choose actuator systems for adjustments, tilting, pushing, pulling and lifting with thrusts up to 10,000 N.

The electric linear actuator has a variety of very different applications. From healthcare to agriculture, comfort furniture, office interior, or industrial automation – the number of possibilities is almost endless.

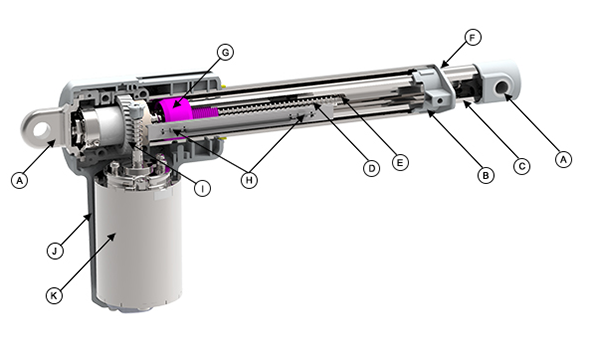

In order to have a better foundation and understanding of how an actuation system works, we will now look at the components that go into manufacturing an electric linear actuator.

A. Front / Rear Clevis - Attachments on the front and rear of the actuator that allow it to be mounted to the application.

B. Outer Tube - Also known as the cover tube. This extruded aluminum or steel tube protects the outside of the linear actuator and houses all of the inner components of the actuator.

C. Inner Tube - Also known as the extension tube, drive tube, translating tube or piston. This tube is usually made out of aluminum or steel. While retracted, the inner tube is where the spindle is located. This tube is attached to the threaded drive nut and extends and retracts when the nut moves along the rotating spindle.

D. Spindle - Also known as the lead screw, rotating screw or lifting screw. This part of the linear actuator rotates, extending or retracting the nut/inner tube, which creates a linear motion. Our steel spindle ensures durability and strength. The spindle can be threaded in different ways for various load and speed capabilities. Additional details of this will be covered in another section.

E. Safety Stop - Located on the end of the spindle, its function is to prevent the inner tube from overextension.

F. Wiper - A sealing component attached to the end of the outer tube which prevents contaminants like dust and liquids from entering the spindle area of the actuator. It also ensures a proper seal between the inner and outer tubes which influences the IP rating of the linear actuator.

G. Drive Nut - The nut, which can be acme or ball, is attached to the inner tube and travels along the spindle. The nut is the component that allows extension or retraction of the inner tube. It can be made of metal or plastic and is sometimes keyed to prevent inner tube rotation.

H. Limit Switches - Limit switches control the fully extended and retracted position of the inner tube by electrically cutting current to the motor. These switches prevent the actuator from over extending or over retracting. In addition to cutting current, limit switches can also be used as a signal sending device.

I. Gear - A gear is made of steel or plastic and mates with other gears to alter the relation between the speed of a driving mechanism (such as the engine of a vehicle) and the speed of the driven parts (the vehicle’s wheels). The gear connected to a power source, such as the motor, is called the "drive gear".

J. Motor Housing - The motor housing contains all the internal parts to the gear motor without leaving anything exposed for external damage.

K. DC Motor - The DC (Direct Current) motor is where all the power is generated for the electric linear actuator.