Why can't the load of servo electric cylinder be too large?

Apr 16 , 2025

The load capacity of servo electric cylinders cannot be very high mainly due to the following reasons:

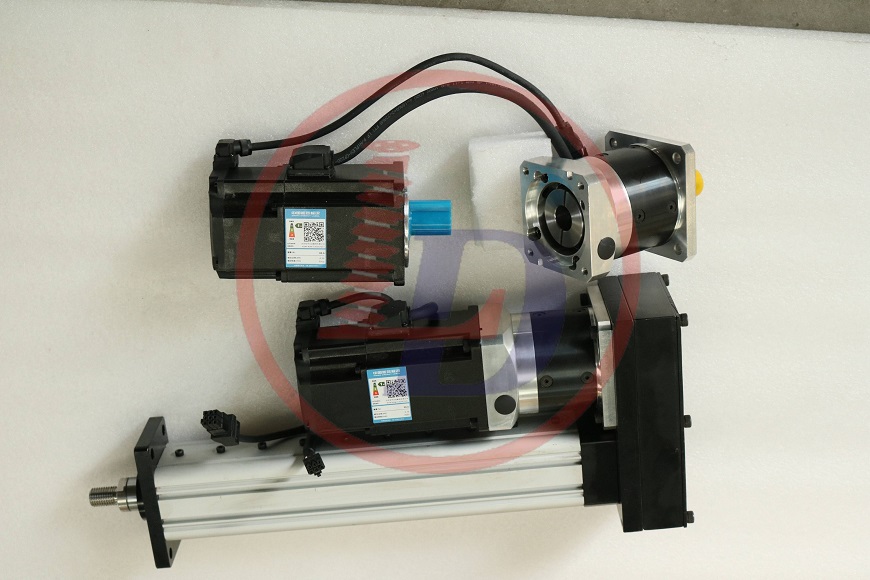

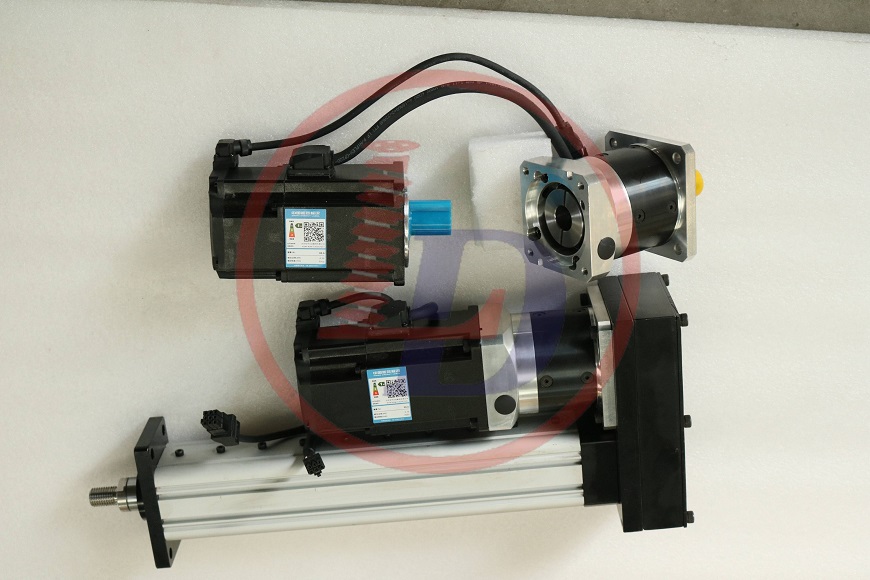

1. Servo motor power limitations: Servo electric cylinders are driven by servo motors, which have limited power. When the load is too large, the motor may not be able to provide sufficient torque to move the load, potentially resulting in motor overload or even burnout.

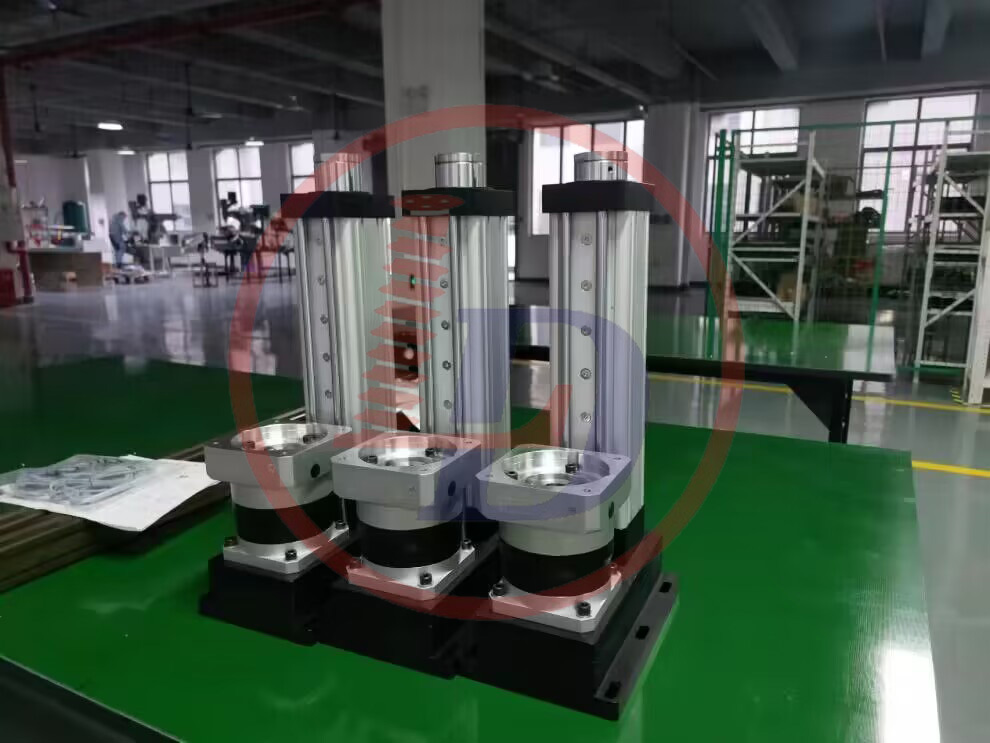

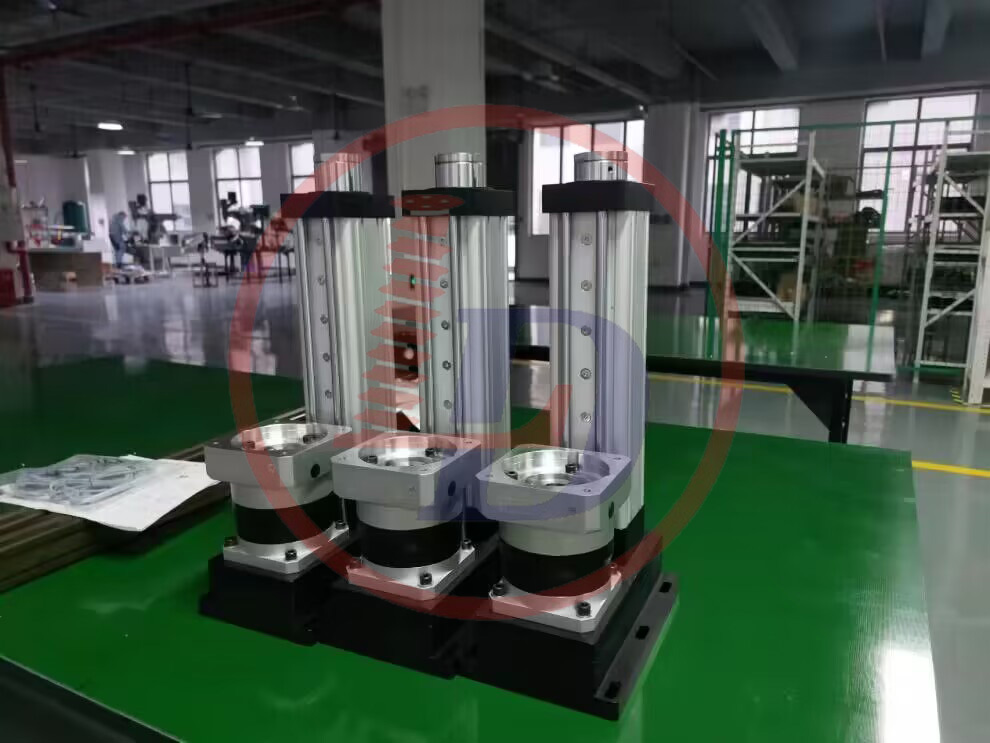

2. Transmission system limitations: Servo electric cylinders typically use mechanical transmission components (such as gears or ball screws) to transfer motion from the motor to the load. Excessive load can put too much stress on these components, leading to wear, damage, or failure.

3. Control system responsiveness: Servo control systems regulate motor operation by adjusting current and voltage. When the load is too heavy, the system may not be able to control the motor precisely, leading to positioning errors, system shutdowns, or overload protection activation.

4. Efficiency issues: High loads can reduce the operational efficiency of the electric cylinder, causing increased heat generation. Excessive load may also affect the effectiveness of the cooling system, raising the system temperature and shortening the lifespan of the electric cylinder.

5. Decreased precision and stability: Servo electric cylinders are typically designed to deliver high-precision motion within a specified load range. Overloading can reduce accuracy and compromise system stability, possibly causing vibrations or abnormal noises.

Therefore, when selecting a servo electric cylinder, it is essential to choose a model that matches the specific application requirements. Ensuring the load remains within the design limits of the cylinder is critical to avoid overload and ensure reliable operation.