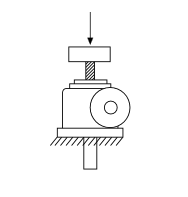

For translating worm gear screw jacks, there are several common mounting forms.

Without guide, the screw is the only support for the load.So the screw must be strong enough and can prevent the buckling.

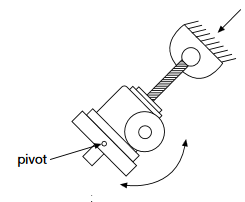

In a trunnion mounting arrangement, the screw has a pivot on the end and the jack body is mounted on a large pivoting frame, or trunnion. This type of mounting is particularly common in the antenna industry. In practice, the pivot should be as close to the centerline of the internal nut as design permits. This will eliminate moment loads caused by loose threads.

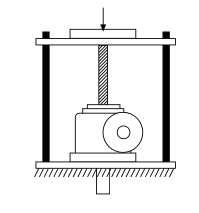

Guided loading is often termed "fixed-fixed" loading. With guided loading, both ends of the column are rigidly held – the jack body is bolted firmly to a sturdy base, and the load travels on slides, bearings, rollers or other means. The guides should be snug enough to prevent any side load or moment load from reaching the screw. Use the "guided" row on the appropriate Column Loading charts.

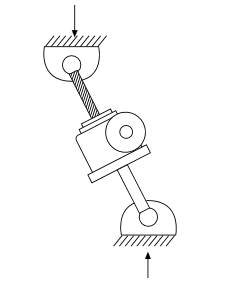

Double-clevis jacks have less load capacity than the other common mounting configurations. A double-clevis jack has pivots or clevises at both ends: one on the screw tip and one on the end of the protection tube. This tends to weaken it as a column by creating eccentric loads on the screw. This eccentricity tends to increase with greater distance and higher loading. For this reason, double-clevis jacks are limited both in capacity and maximum length. Double-clevis mounting differs from trunnion mounting because the pivot is located farther from the jack body.

At last,lets’s see some actual product pictures.

acme screw jack with Trunnion mounting

electric screw jacks with guides

manual screw jack with Trunnion mounting

small screw jack horizontal mounting