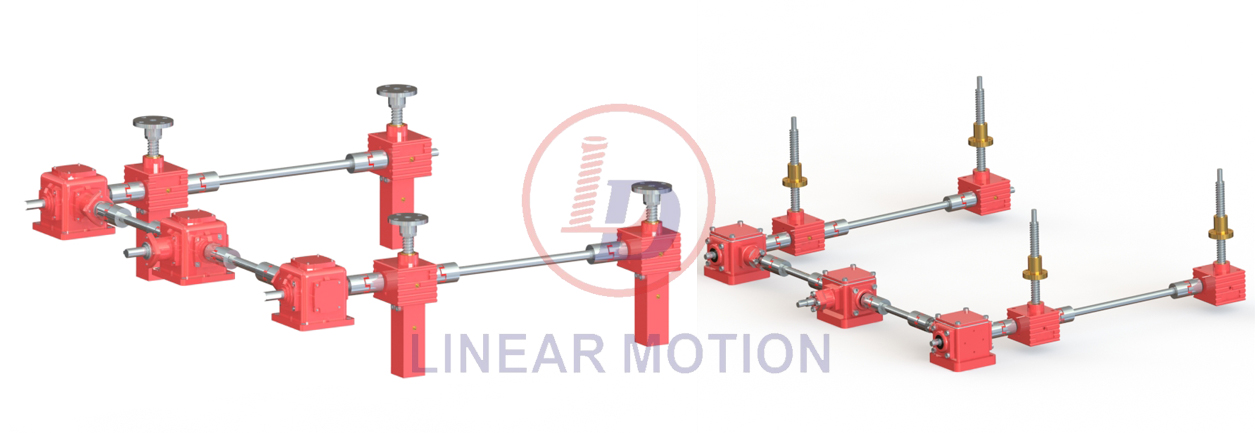

The screw jack system is widely used in situations with long spans and excessive loads. The use of screw jacks typically involves a multi-unit synchronized configuration. This approach ensures that the load on each individual screw jack does not exceed its capacity, guaranteed sychronized movement of all units to prevent lateral forces, and ehances overall stability and safety of the solution.

The desigan phase for a synchronized screw jack system is crucial,requiring customers to provide relvent data and considering installation space, operating conditions, limit switches, and other aspects. However, after completion and production delivery, on-sit installation at the customer's premises is equally important. We need to pay attention to various issues such as center height alignment,coaxiality, guide devices,and gearbox orientation determination.

Today we want to discuss how to avoid excessive deviations during the multi-unit screw jack system.First, let's start with the perparation steps: After receiving the screw jacks from the customer, it's necessary to ensure that the output and input shafts of units like gearbox and motors are at the same horizontal level. If there is a difference in center height, you can chosse to add appropriate thickness washers to make them consistent. When connecting with couplings or connection rods, it's necessary to calibrate coaxiality to prevent tilting or binding situations.

If a lifting platform is required, attention must be paid to its installation. We need to ensure that the mountibng surface of the screw or nut is at the same horizontal heigth, and the mounting surface of the screw jack should also remain level.Additionally, adjust the mounting holes of the screw head(or nut mounting holes)so that they align with the mounting holes of the support platform before installation installing it. It's important to note that during installation,lateral forces should not be applied to the screw. Lastly, to avoid excessive deviation when multiple screw jack system are installed, we must confirm that there are no errors in the dimensional deviations of each axis before connecting the equipment.Before assembling the screw jack with the driven source and other devices., check for dimensional deviations in shaft diameters,keys, and keyways to prevent damage to bearings from over-tightening or affect power transmission from under-tightening.After installation, lubricate all necessary parts and conduct test runs.If any issues arise during testing, immediately stop operation and only restart once everything is confirmed to be normal.