Ball worm gear screw jack is widely used for lifting.It has following advantages:

•Are suitable for higher travel speeds and moderate to high duty cycles

•Move loads faster and with less horsepower

•Are good for moving loads with longer continuous travel

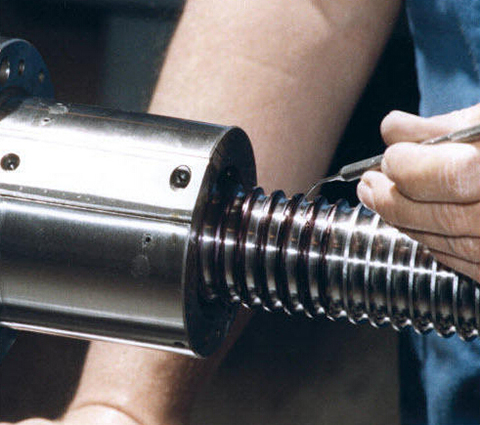

Ball screw is an important part of the ball worm screw lift.How to maintain and store the ball screw? Let’s see the following information.

Ball Screw Maintenance (Lubrication and Cleanliness)

A ball screw must be properly lubricated and kept clean at all times. Otherwise its life will be reduced. When ball screws are not lubricated, the wear life drops by as much as 85-percent. Lubrication reduces friction, prevents corrosion and allows the ball screw to operate more efficiently. Oil and grease are both used for lubrication. Grease is not normally used in low temperature or high speed applications. Graphite grease or grease with suspended solid particles are never used because they tend to clog the ball return system.

The oil supply should insure a light film of clean oil with filtration levels of three (3) microns or less at all times. Lubrication contaminated with dirt and chips increases friction. Balls traveling over metal chips in the ball thread raceway cause "spalling" and the ball screw fails.

Use lubricants recommended by the machine tool manufacturer. As in the case of any high precision assembly, contamination by chips, dirt or other foreign matter will cause and ultimately induce ball screw failure. Limited protection is provided by seals or wipers. Bellows or telescopic covers are recommended if the environment has a high concentration of contaminants. Periodic inspection for cleanliness and lubrication will extend the life of the ball screw.

Storage of Ball Screw Unit

The transport container stores the units stored in the plastic sleeve in the original shipping container. Place the ball screw assembly in the protective cover until the actual installation in the machine begins. Dirt, dust or debris will precipitate on the assembly, and the wear of the ball raceway will begin immediately after the machine is running. If stored for a long time, turn the container at intervals of three months to prevent oil from spreading over the screws.