Slewing ring is an important part for types of slewing drives .Let’s talk about the slew ring bearing today. As we know, large-diameter (e.g., 8" to 10') bearings are easy to get damaged in heavy-duty applications where rotations are frequent. These heavy-duty applications mainly mean cranes, excavators and tunnel boring machines, a slewing ring bearing must simultaneously handle a complex load spectrum that covers diverse combinations of thrust, radial and tilting moment loading.

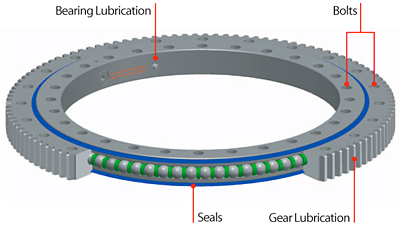

Fortunately, there's an easy way to protect your investment in these custom-engineered bearings. It's called regular maintenance, and it can prevent 96% of slewing ring bearing failures. To maximize bearing life, simply follow these tips—bearing and gear lubrication, torque checks on bolts, and seal inspection.

Bearing Lubrication A bearing should be lubricated at regular intervals with heavy-duty, extreme-pressure grease.

Most large bearings have gear teeth that require lubrication, and those requirements are different than they are for the bearing itself. Since the meshing action of the teeth tends to squeeze out lubricant, gears should be lubricated every eight hours on slow-rotating or intermittently rotating equipment.

In order to make sure the seals on the bearing are intact,the seals should be visually inspected periodically. Many people ignore the importance of seals, but they are very helpful in preventing bearing raceway contamination.

The mounting bolts should be twisted to the correct position and checked regularly to ensure proper pretensioning. Incorrect pre-tensioning bolts may fail, causing damage to the equipment and, more importantly, causing injuries to workers.