Introduction

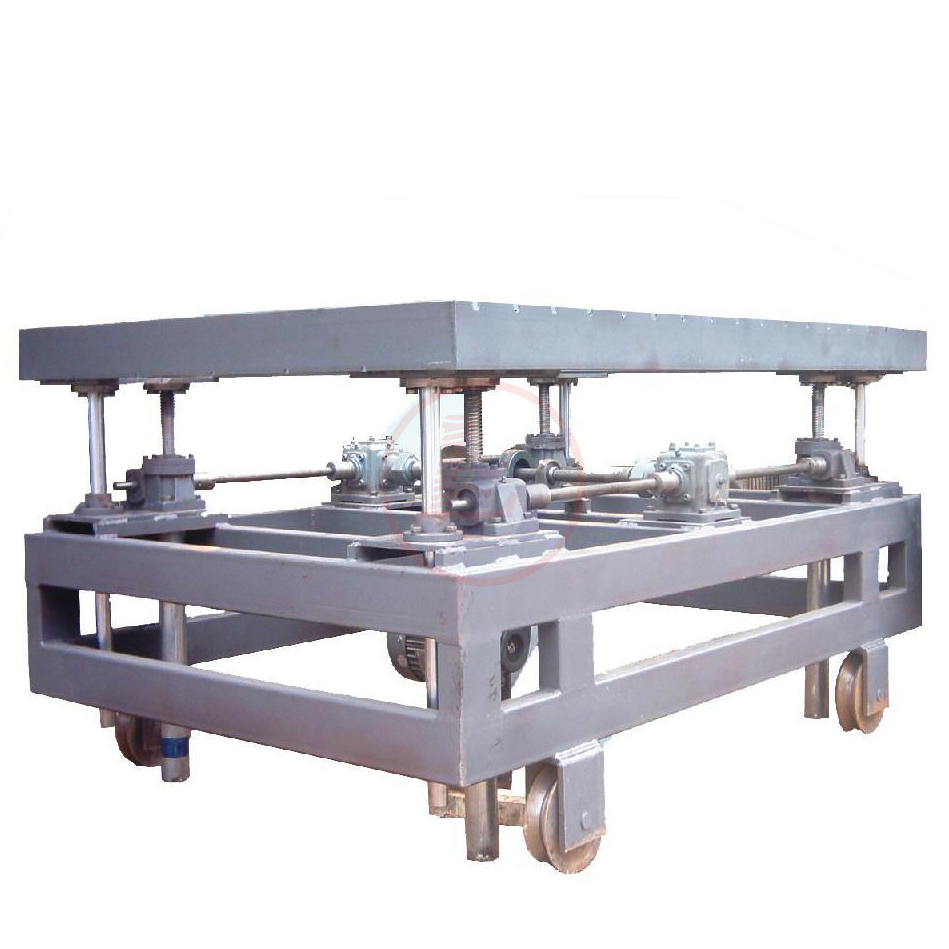

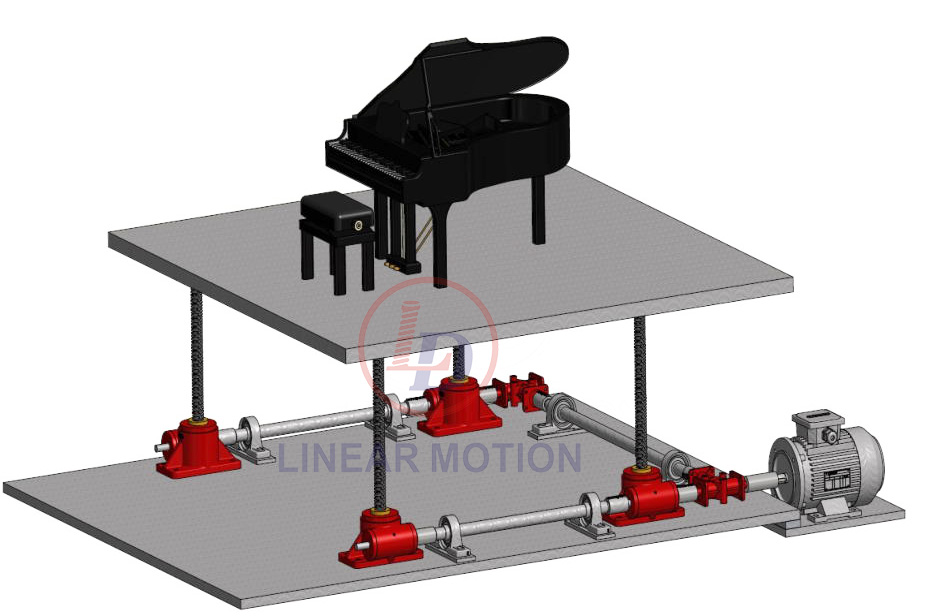

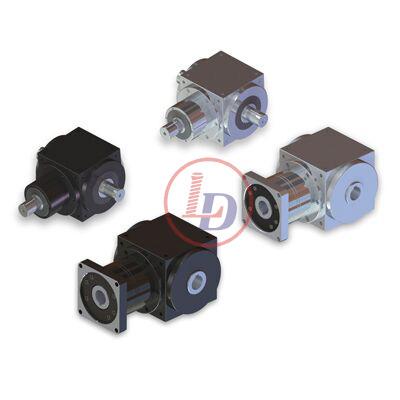

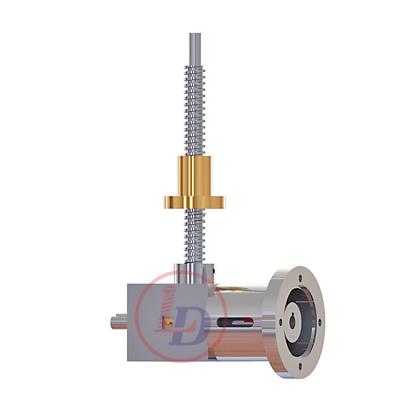

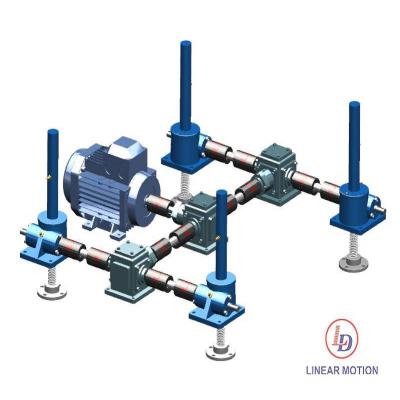

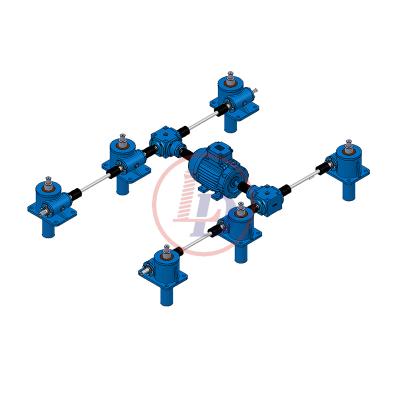

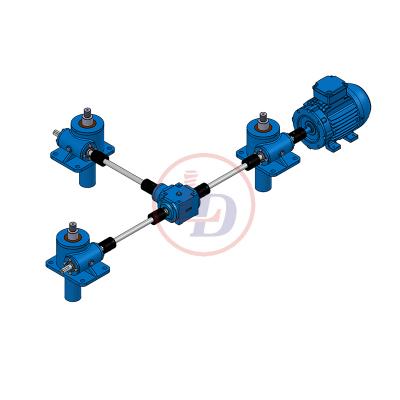

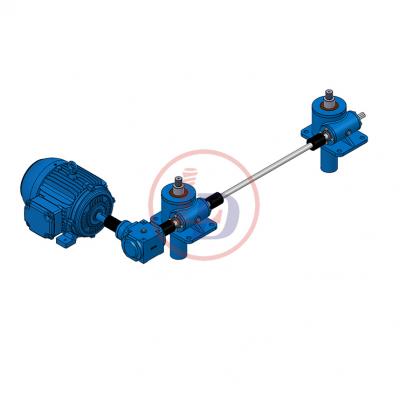

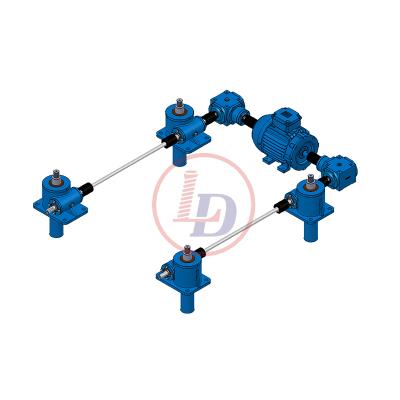

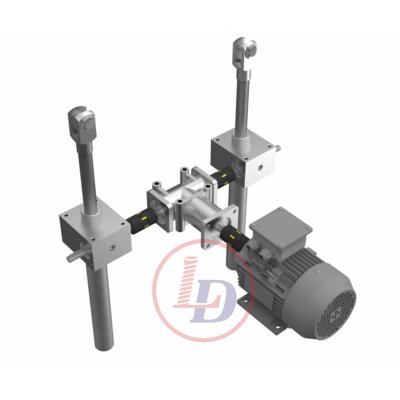

Screw jacks lifting system structures include miter gearboxes, screw jacks, electric motor or gear reducer, hand wheel, pillow block bearings, jaw couplings and line shaftings.

Compared to fast speed hydraulic lifting system and pneumatic lifting system, screw jacks lifting system is not only for the simple load-supporting from several kilograms to heavy duty several hundreds tons, but also have many advantages such as self-locking without brake or locking mechanism, precisely positioning, full synchronization, manual operated or electric motor driven, quiet environment, easy installation and operation, maintenance free.

Screw jack system application